2022 China New Design Alumina Cylinder - Wear Resistant Ceramic Lining Tile – Chemshun

2022 China New Design Alumina Cylinder - Wear Resistant Ceramic Lining Tile – Chemshun Detail:

Description

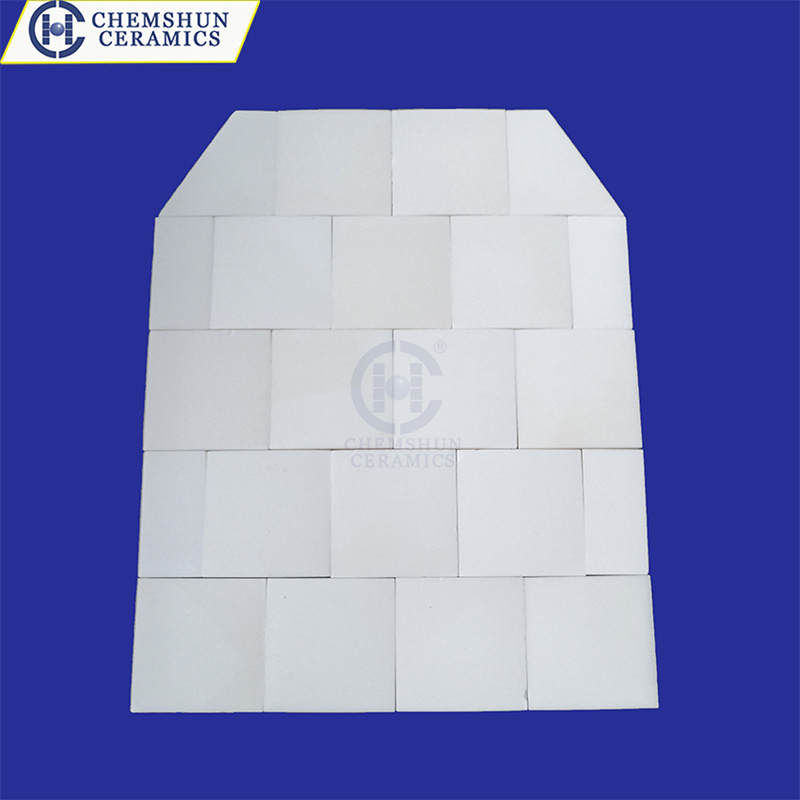

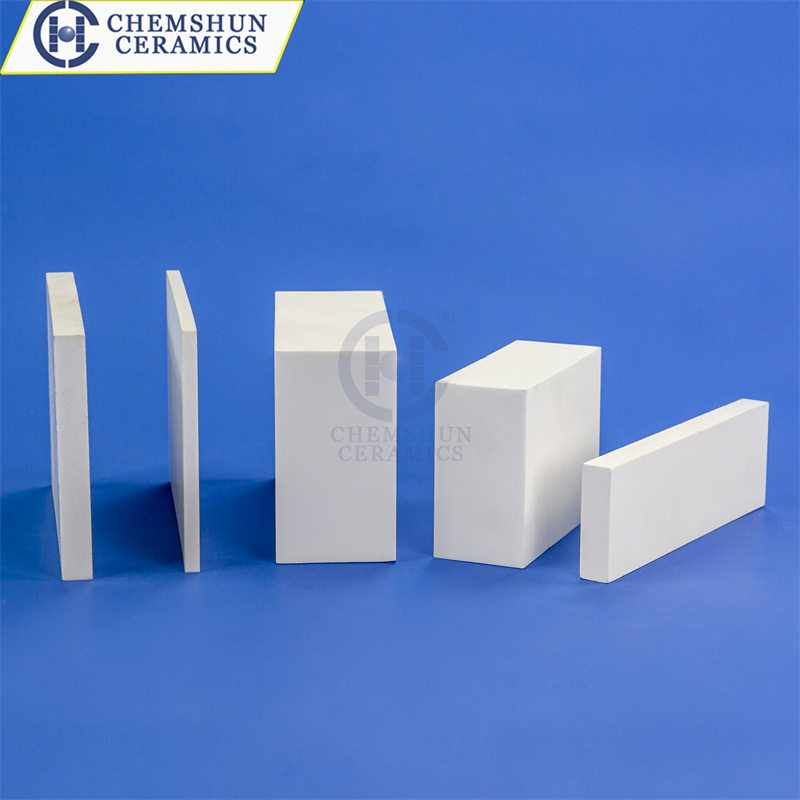

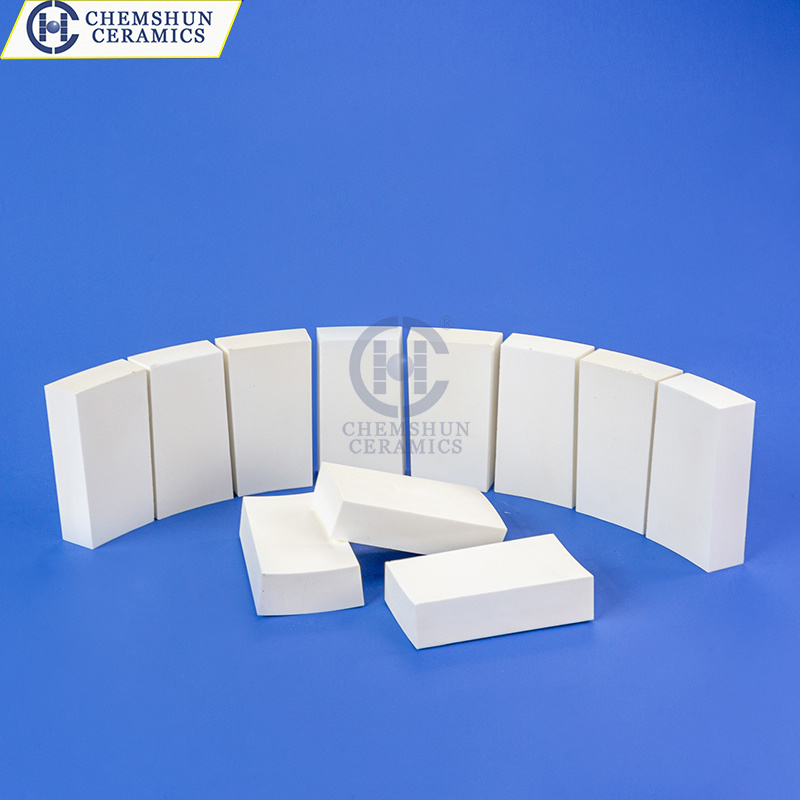

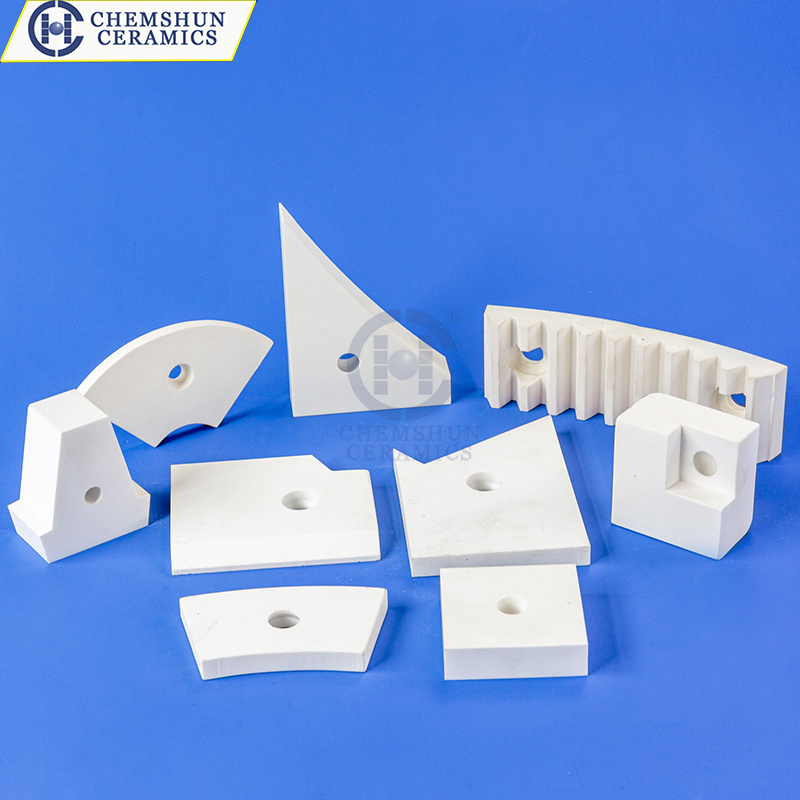

Chemshun ceramic lining tiles help users reduce their downtime and improve their productivity Chemshun could afford customers the optimum lining tiles accommodate the detailed equipment wear protection demand with wear ceramic lining: plain tile, weldable tile, trapezoidal tile, curved & lock tile, and engineering tile with special geometries, some mosaic pieces is best abrasion materials for vulcanized in rubber sheet. Here we intorduce some chemshun alumina ceramic tiles for the Hopper, chute, cyclone, pipe tunks etc equipment information for your reference.

Alumina wear tile liner techcnical date

|

S.No. |

Attributes |

Unit |

Chemshun 92 |

Chemshun 92 |

Chemshun 95 |

Chemshun ZTA |

|

1 |

Alumina Content |

% |

92 |

92 |

95 |

70-75 |

|

ZrO2 |

% |

25-30 |

||||

|

3 |

Density |

g/cc |

≥3.60 |

≥3.60 |

>3.65 |

≥4.2 |

|

4 |

Color |

- |

White |

White |

White |

White |

|

5 |

Water Absorption |

% |

<0.01 |

<0.01 |

0 |

0 |

|

6 |

Flexural Strength |

Mpa |

270 |

300 |

320 |

680 |

|

7 |

Moh’s Density |

Grade |

9 |

9 |

9 |

9 |

|

8 |

Rock Well Hardness |

HRA |

80 |

85 |

87 |

90 |

|

9 |

Vickers Hardness(HV5) |

Kg/mm2 |

1000 |

1150 |

1200 |

1300 |

|

10 |

Fracture Toughness(Min) |

MPa.m1/2 |

3-4 |

3-4 |

3-4 |

4-5 |

|

11 |

Compressive strength |

Mpa |

850 |

850 |

870 |

1500 |

|

12 |

Thermal Expansion Coefficient(25-1000℃) |

1×10-6/℃ |

8 |

7.6 |

8.1 |

8.3 |

|

13 |

Maximum operation temperature |

℃ |

1450 |

1450 |

1500 |

1500 |

Application in Industries

| Industry | Equipment system | Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute, bunker, pulley lagging, discharge cone |

| Raw mill system | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Cement mill system | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Ball mill system | Pulverizer exhauster’s body and vane wheel, powder concentrator’s body, pulverized coal’s pipeline, hot air duct | |

| Sintering system | Inlet/outlet bend, wind value plate, cyclone, chute, dust collector’s pipe | |

| Afterheat system | Separator’s pipeline and wall | |

| Steel | Raw material feeding system | Hopper, silo |

| Batching system | Mixing bunker, mixing barrel, mixing disk, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Dedusting and Ash discharge system | Dedusting pipeline, bend, y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone, separation buffles, outlet pipe, pulverized coal’s pipeline, burner cone | |

| Ball mill | Classifier, cyclone separator, bend, powder concentrator’s inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine, coal hopper, coal feeder, orifice |

| Ball mill system | Separator’s pipe, elbow and cone, coal mill’s elbow and straight tube | |

| Medium-speed mill | coal mill body, separation buffles, cone, pipeline, elbow | |

| Fall mill | Pulverized coal’s pipeline and elbow | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Ash discharge system | Fan duster’s shell, pipeline | |

| Port | Transporting material system | Bucket wheel machine’s disk and hopper, transfer point’s hopper, unloader’s hopper, |

| Smelting | Transporting material system | Measuring hopper, coke hopper, vibrating screen’s chute, head valve, Intermediate bin, tail bin |

| Batching system | batch hopper, mixing machine | |

| Burning system | Ash bucket, pump calcine tube, hopper | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Chemical | Transporting material system | Hopper, silo |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine, coal hopper, coal feeder |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper, silo |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for 2022 China New Design Alumina Cylinder - Wear Resistant Ceramic Lining Tile – Chemshun , The product will supply to all over the world, such as: Peru, Nepal, Lithuania, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.