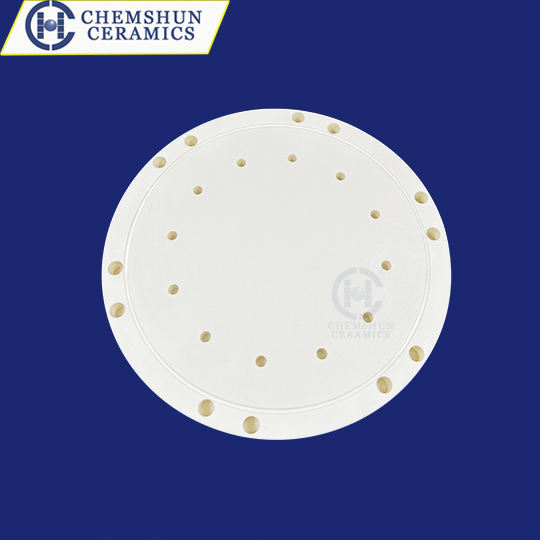

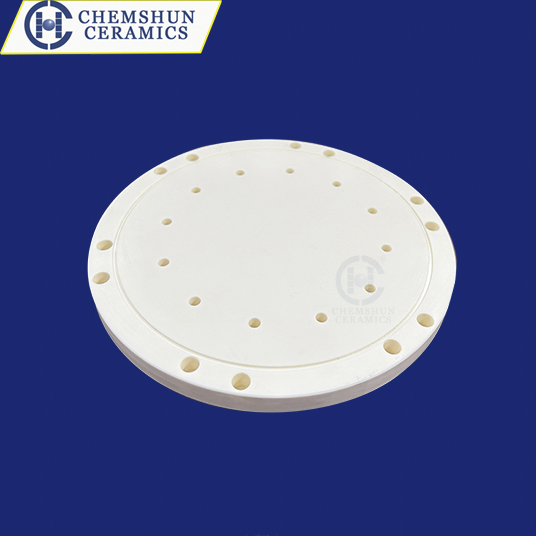

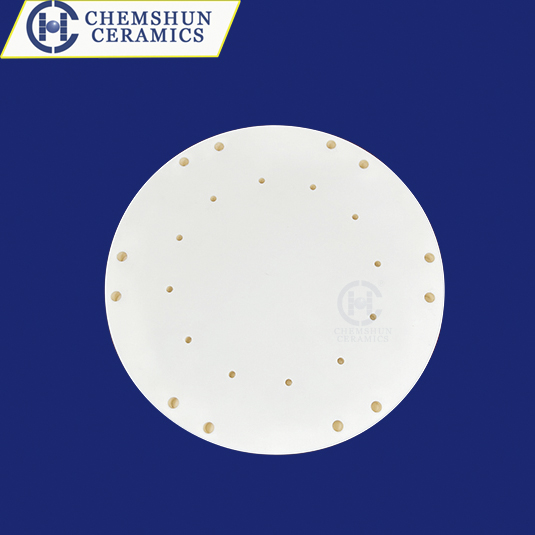

99.7% Alumina Wafer Polishing Plate with Hole

Product features

High purity alumina, 99.7%-99.9% alumina.

High mechanical strength, high wear resistance, high electrical insulation, high chemical stability, good heat resistance and corrosion resistance. At present, the use of ceramic grinding disc grinding semiconductor silicon wafer is the most superior and cutting-edge grinding method. The double-sided grinding process is used to grind the cut silicon wafer, and the quality of the grinding wafer is improved by improving the grinding process (disc material, grinding fluid, grinding pressure and grinding speed, etc.). In particular, the use of ceramic plates instead of cast iron plates, to avoid grinding on the main surface of the wafer caused by scars or pollution, reduce the introduction of metal ions, can reduce the subsequent processing of silicon, shorten the subsequent process (corrosion) time, improve production efficiency, and reduce the loss of silicon processing, greatly improve the utilization of silicon.

Chemical/physical parameters

| property | |

| Density (g/cm3) |

3.94-3.97 |

| Purity (%) |

99.7-99.9 |

| Vickers Hardness (GPa) |

≥17 |

| Three point bending strength (MPa) |

440-550 |

| Thermal diffusion coefficient (Cm2/s) |

0.0968 |

| Elastic modulus (GPa) |

356 |

Product Specifications

Φ850mm, thick 45mm or less of high purity alumina disc, ring (size can be customized).

We can also produce the following specifications of high-end ceramics:

1, 1500x600x25mm below the long board, strip, square board, sheet;

2. Guide rails below 1000x45x45mm;

3, φ300~600x length of 500mm or less empty pipe, cylinder, electric vacuum tube, etc.

4, can customize a variety of shapes and specifications of high purity alumina ceramic products.

Advantages of Chemshun Ceramics

We have independent intellectual property rights of PIBM self-curing molding process, specializing in the production of high-quality fine ceramic components. The new process breaks through the deformation and cracking of large size ceramic wet billet in the process of preparation, and the product performance is significantly optimized compared with that of large ceramic parts prepared by traditional methods.

The alumina ceramic polishing disc produced by Pingxiang Chemshun Ceramics Co., Ltd. adopts PIBM self-curing molding process. The international advanced PIBM technology has successfully solved the key problem of crack deformation of large diameter alumina. PIBM ceramic technology will open another bright window for the ceramic industry. We not only produce high quality alumina ceramic polishing plates, but also include other series of large size high purity alumina ceramics, such as 1200*500*20mm ceramic substrates for LCD manufacturing equipment, semiconductor transmission rails, vacuum components, general mechanical parts, bulletproof ceramics.