Chinese Professional Wear Resistant Silicon Carbides - Reaction Bonded Silicon Carbide – Chemshun

Chinese Professional Wear Resistant Silicon Carbides - Reaction Bonded Silicon Carbide – Chemshun Detail:

Advantages of Reaction Bonded Silicon Carbide

1) Low density.

2) Corrosion resistance.

3) Wear resistance.

4) Oxidation resistance.

5) Abrasion resistance.

6) Good thermal shock resistance (due to low thermal expansion coefficient and high thermal conductivity).

7) Excellent Strength at high temperature.

8) Good dimensional control of complex shapes.

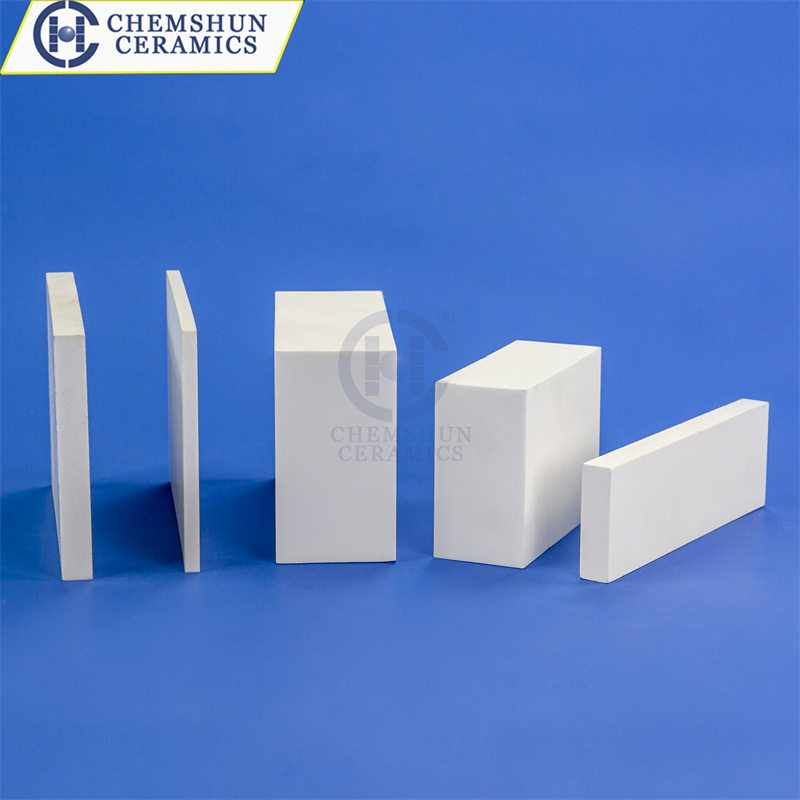

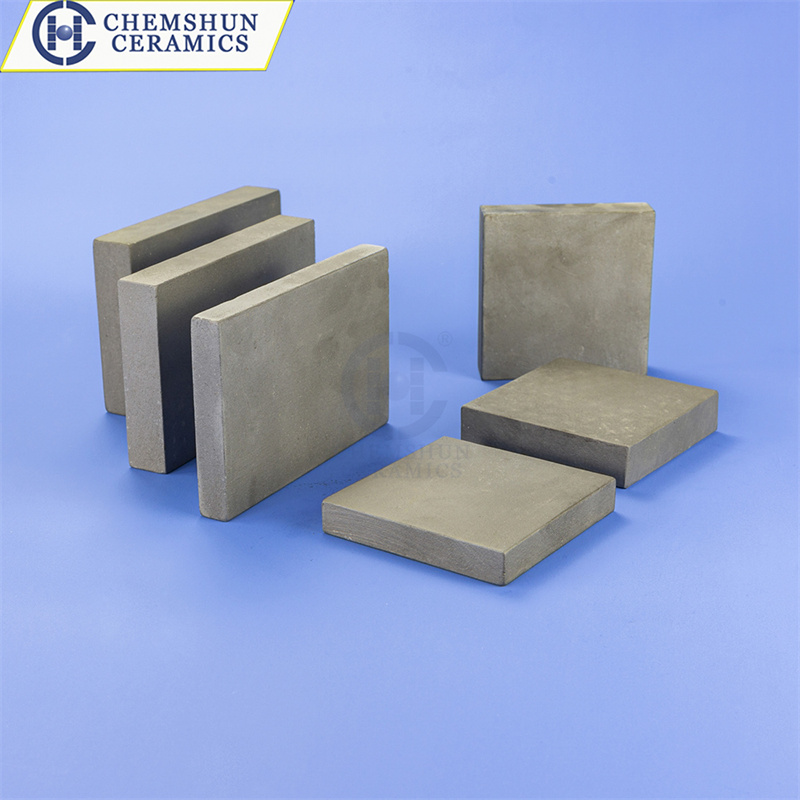

Wear Resistant products: Silicon carbide plate, Silicon carbide brick, Pipe lining, Pipe Cone,cyclone,etc.

Kiln furniture: Plate, Beam, Roller, Burner Nozzle,Round beam ,square beam,hole beam.Crucible,Sagger,etc.

Others: Desulfurization nozzles

Application of Reaction Bonded Silicon Carbide:

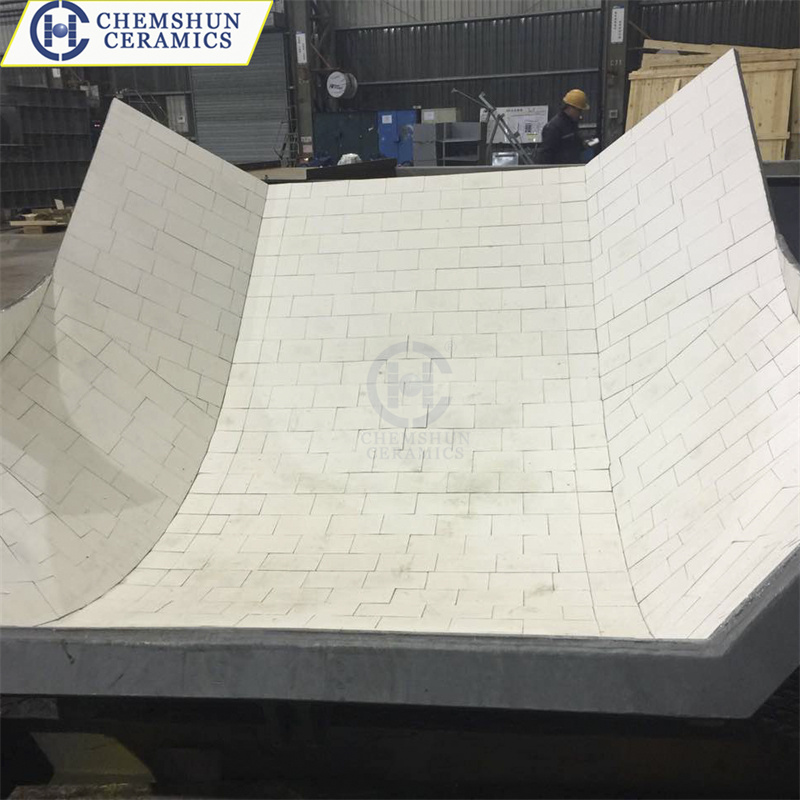

Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, Nozzles,flow control chokes and larger wear components in the mining as well as other industries.

Main Parameter

| Properties | Units | SiSiC/RBSIC |

| Bulk density (SiC) | V01% | ≥85 |

| Bulk density | g/cm3 | 3.01 |

| Apparent porosity | % | <0.1 |

| Modulus of rupture at 20℃ | Mpa | 250 |

| Modulus of rupture at 1200℃ | Mpa | 280 |

| Modulus of elasticity at 20℃ | Gpa | 330 |

| Fracture toughness | Mpa*m1/2 | 3.3 |

| Thermal Conductivity at 1200℃ | w.m-1.k-1 | 45 |

| Thermal expansion at 1200℃ | a×10-6/℃ | 4.5 |

| Thermal shock resistance at 1200℃ | Very good | |

| Coefficient of heat radiation | <0.9 | |

| Max.working temperature | ℃ | 1350 |

Size

can be customized according to customer requirements.

Service

We accept custom orders.

If you want to know more product information, welcome to cotact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Chinese Professional Wear Resistant Silicon Carbides - Reaction Bonded Silicon Carbide – Chemshun , The product will supply to all over the world, such as: Mumbai, Algeria, Birmingham, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!