Engineered Ceramic Wear Plate

Products Description

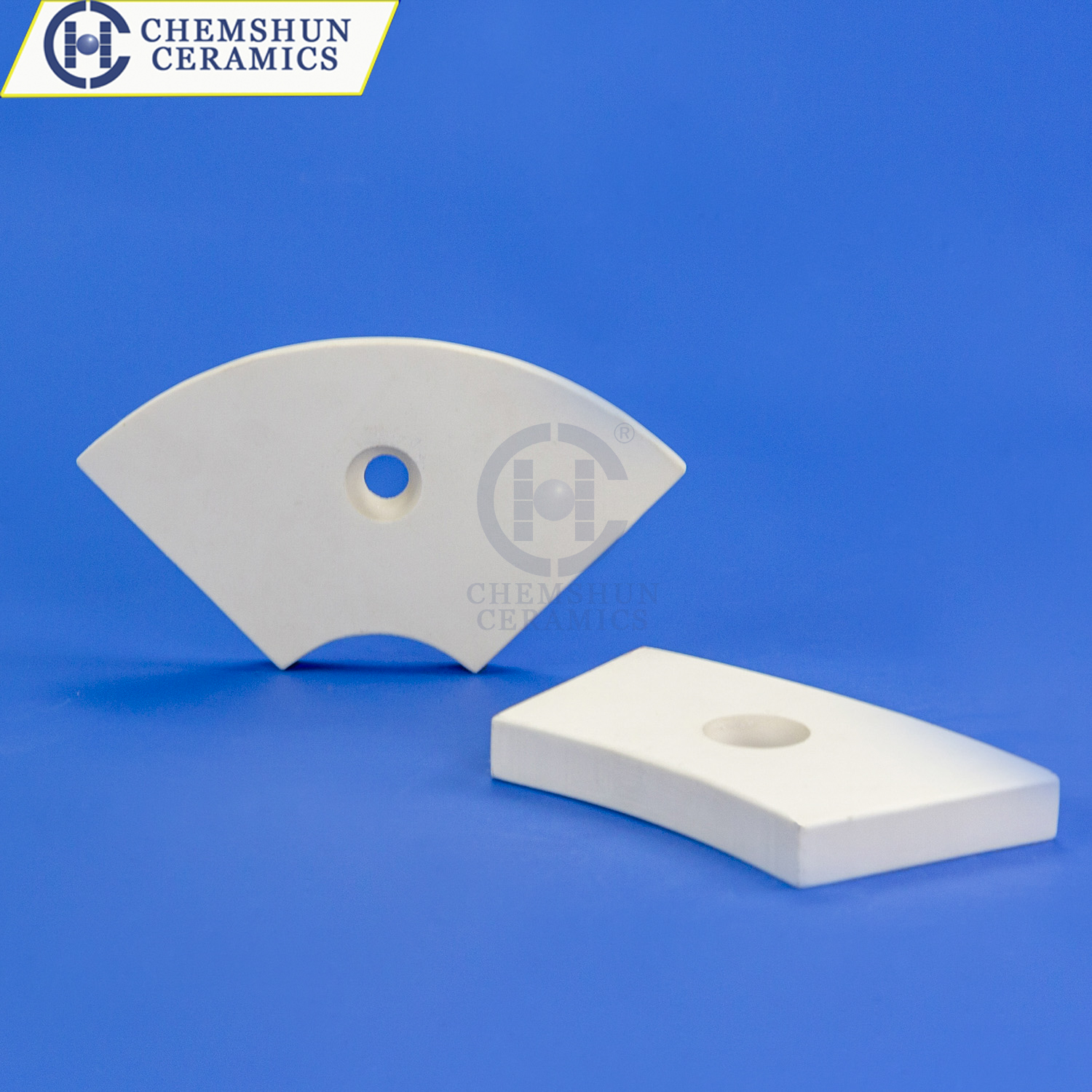

Wear resistant pre-engineering tile in a variety of geometric shapes from simple to complex,the ceramics can be engineered or mould to specific shapes to customer’s requirement.

Ceramic lined equipment like pipes,bends,chutes,hoppers,bunkers, etc. Alumina ceramic liner has excellent abrasion resistance,hard resistant,corrosion resistance,it is widely used in the mining,power plant,steel plant,cement industries like chutes, hopper,bunker,cyclone,convey belt, etc. This alumina ceramic product make cost effective performance like reduce un-necessary down time and maintance,and prolong the equipment from quick abrasion

Feature:

· Excellent corrosion resistance property

· Easily handled size and weight

· Excellent heat resistance property

· Excellent impact resistance property

· Fast and safe installation

· Lower production and maintenance cost

Chemshun Ceramic Advantages

· Professional technical team to afford CAD designs

· Professional installation team to afford install service

· Well established process as per international standards

· Accept the standard and pre-engineered tiles

Special Shape Including:

· With triangle

· With multihole

· With arc

· With polygon

· With chamfer

Etc.

Technical Data Sheet:

| S.No. | Attributes | Unit | CHEMSHUN 92 I | CHEMSHUN92 II |

| 1 | Alumina Content | % | 92 | 92 |

| 2 | Density | g/cc | ≥3.60 | ≥3.60 |

| 3 | Color | - | White | White |

| 4 | Water Absorption | % | <0.01 | <0.01 |

| 5 | Flexural Strength | Mpa | 270 | 300 |

| 6 | Moh’s Density | Grade | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 3-4 | 3-4 |

| 10 | Compressive strength | Mpa | 850 | 850 |

| 11 | Thermal Expansion Coefficient (25-1000ºC) |

1×10-6/ºC | 8 | 7.6 |

| 12 | Maximum operation temperature | ºC | 1450 | 1450 |