Factory Cheap Hot Silicon Carbide Body Armor - Reaction Bonded Silicon Carbide – Chemshun

Factory Cheap Hot Silicon Carbide Body Armor - Reaction Bonded Silicon Carbide – Chemshun Detail:

Advantages of Reaction Bonded Silicon Carbide

1) Low density.

2) Corrosion resistance.

3) Wear resistance.

4) Oxidation resistance.

5) Abrasion resistance.

6) Good thermal shock resistance (due to low thermal expansion coefficient and high thermal conductivity).

7) Excellent Strength at high temperature.

8) Good dimensional control of complex shapes.

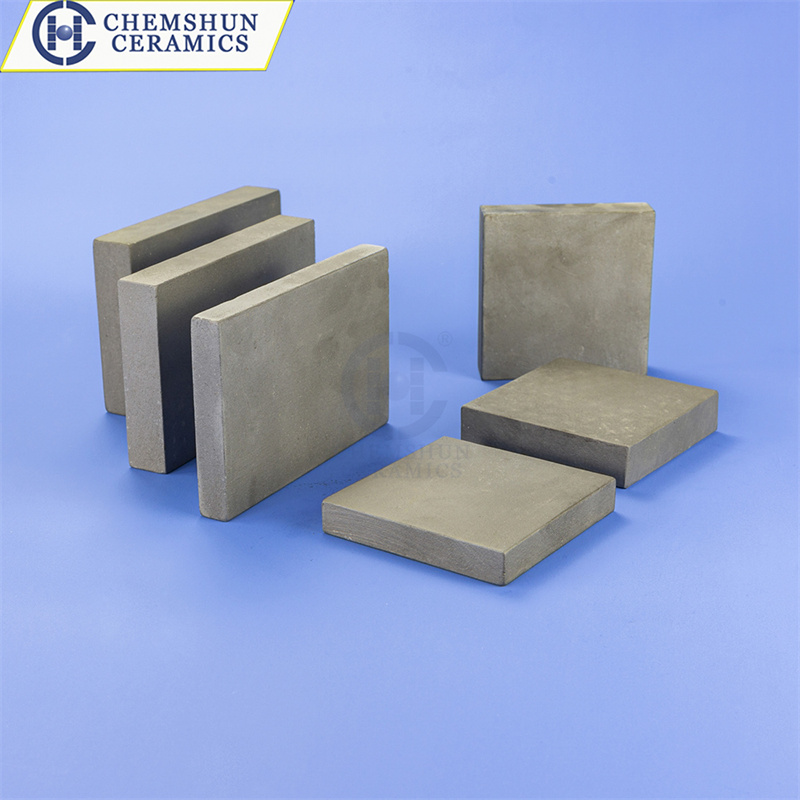

Wear Resistant products: Silicon carbide plate, Silicon carbide brick, Pipe lining, Pipe Cone,cyclone,etc.

Kiln furniture: Plate, Beam, Roller, Burner Nozzle,Round beam ,square beam,hole beam.Crucible,Sagger,etc.

Others: Desulfurization nozzles

Application of Reaction Bonded Silicon Carbide:

Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, Nozzles,flow control chokes and larger wear components in the mining as well as other industries.

Main Parameter

| Properties | Units | SiSiC/RBSIC |

| Bulk density (SiC) | V01% | ≥85 |

| Bulk density | g/cm3 | 3.01 |

| Apparent porosity | % | <0.1 |

| Modulus of rupture at 20℃ | Mpa | 250 |

| Modulus of rupture at 1200℃ | Mpa | 280 |

| Modulus of elasticity at 20℃ | Gpa | 330 |

| Fracture toughness | Mpa*m1/2 | 3.3 |

| Thermal Conductivity at 1200℃ | w.m-1.k-1 | 45 |

| Thermal expansion at 1200℃ | a×10-6/℃ | 4.5 |

| Thermal shock resistance at 1200℃ | Very good | |

| Coefficient of heat radiation | <0.9 | |

| Max.working temperature | ℃ | 1350 |

Size

can be customized according to customer requirements.

Service

We accept custom orders.

If you want to know more product information, welcome to cotact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Factory Cheap Hot Silicon Carbide Body Armor - Reaction Bonded Silicon Carbide – Chemshun , The product will supply to all over the world, such as: Norwegian, Czech republic, Pretoria, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!