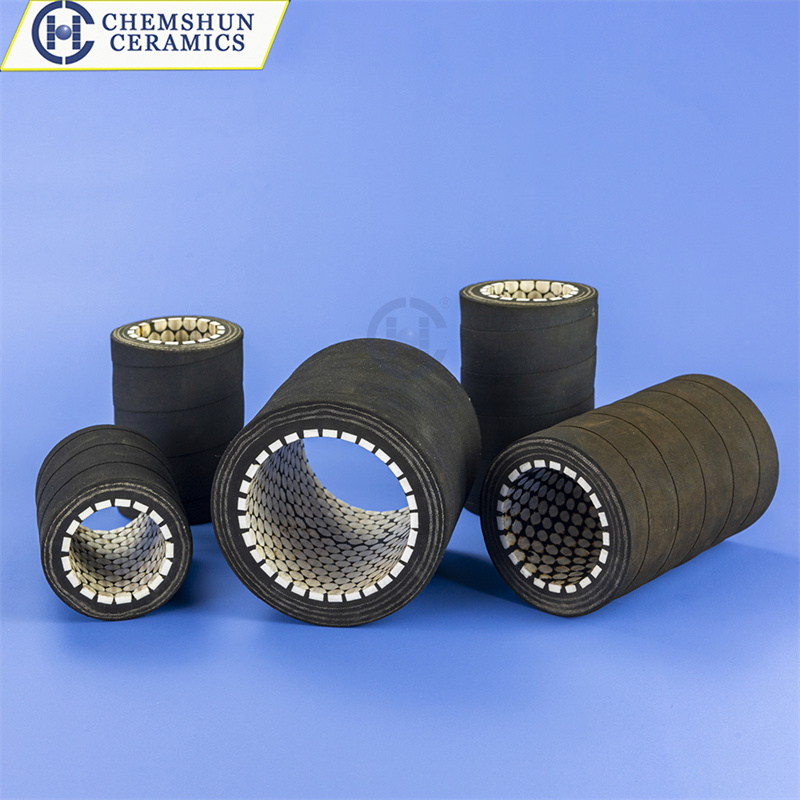

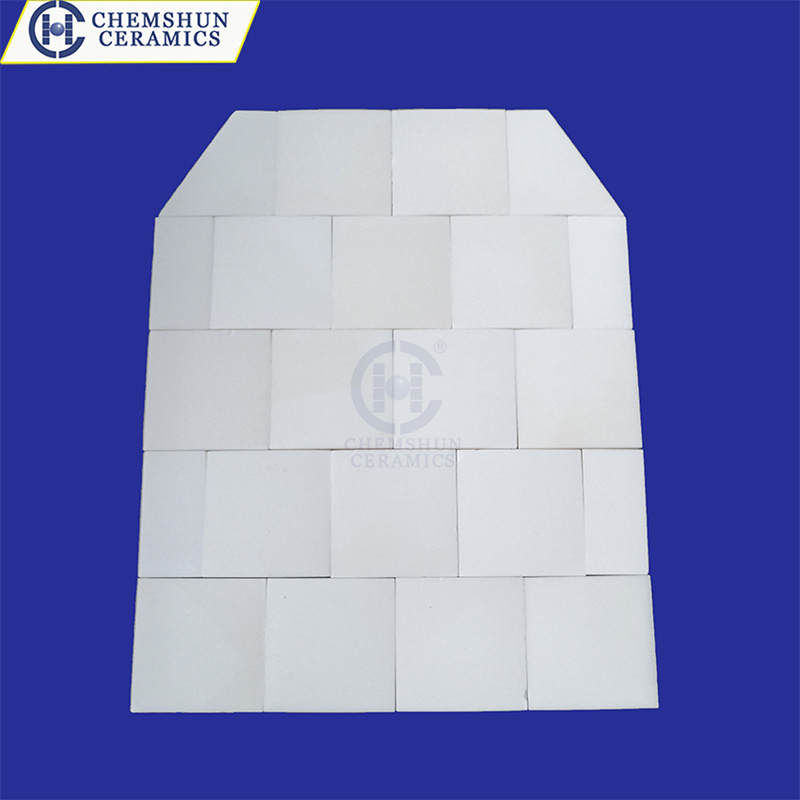

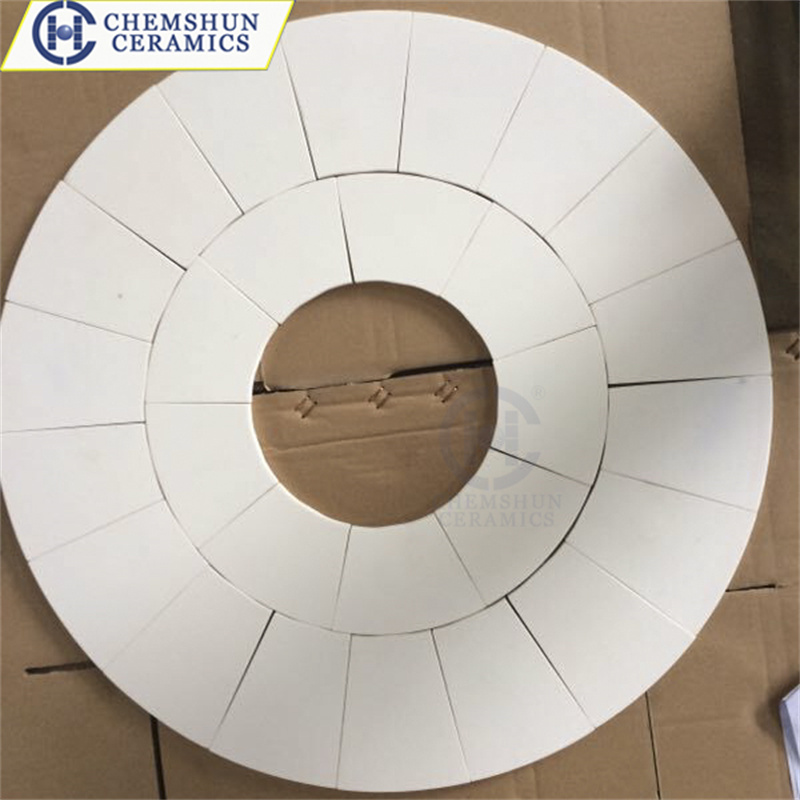

Good quality Alumina Oxide Cylinders - Engineering Ceramic Tile Liner – Chemshun

Good quality Alumina Oxide Cylinders - Engineering Ceramic Tile Liner – Chemshun Detail:

Product advantage

1) High hardness

2) Superior abrasion resistance

3) Corrosion and chemical resistance

4) Light weight with low density

5) Can be applied in all kinds industrial abrasion solution field

Technical data

| Item | Alumina content | Density | Moh’s hardness | Apparent porosity | Crystal size |

| Alumina tile | 92% | >3.6g/cm3 | >9 | 0(%) | 1.3-3 |

| Alumina tile | 95% | >3.7g/cm3 | >9 | 0 (%) | 1-2 |

| Specific gravity (g/cc) | >3.60 |

| Apparent porosity (%) | 0 |

| Flexural Strength (20ºC, Mpa) | 280 |

| Compressive strength (20ºC, Mpa) | 850 |

| Rockwell hardness (HRA) | 80 |

| Vickers hardness (hv) | 1050 |

| Moh’s hardness (scale) | ≥9 |

| Thermal Expansion (20-800ºC, x10-6/ºC) | 8 |

| Crystal Size (μm) | 1.3~3.0 |

Ceramic tile liner size

| Chemshun standard tile liner popular size | |

| Unit (mm) LenghtxWidthxThickness | Unit ( inch) |

| 50x25x3 | 2″x1″x1/8″ |

| 50x25x6 | 2″x1″x1/4″ |

| 50x50x13 | 2″x2″x1/2″ |

| 150x25x6 | 6″x1″x1/4″ |

| 150x25x13 | 6″x1″x1/2″ |

| 150x50x6 | 6″x2″x1/4″ |

| 150x50x25 | 6″x2″x1″ |

| 150x100x6 | 6″x4″x1/4″ |

| 150x100x13 | 6″x4″x1/2″ |

| 150x100x25 | 6″x4″x1″ |

| 150x100x50 | 6″x4″x2″ |

| 100x100x20 | 4″x4″x3/4″ |

| 120x80x20 | 4.7″x3.15″x3/4″ |

| 150x25x6 | 6″x1″x1/4″ |

| 150x25x13 | 6″x1″x1/2″ |

| 114x114x20 | 4.5″x4.5″x0.75″ |

| 228x114x20 | 9″x4.5″x0.75″ |

| Engineering ceramics according to customer’s shape requirement | |

Application in Industries

| Industry | Equipment system | Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute, bunker, pulley lagging, discharge cone |

| Raw mill system | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Cement mill system | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Ball mill system | Pulverizer exhauster’s body and vane wheel, powder concentrator’s body, pulverized coal’s pipeline, hot air duct | |

| Sintering system | Inlet/outlet bend, wind value plate, cyclone, chute, dust collector’s pipe | |

| Afterheat system | Separator’s pipeline and wall | |

| Steel | Raw material feeding system | Hopper, silo |

| Batching system | Mixing bunker, mixing barrel, mixing disk, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Dedusting and Ash discharge system | Dedusting pipeline, bend, y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone, separation buffles, outlet pipe, pulverized coal’s pipeline, burner cone | |

| Ball mill | Classifier, cyclone separator, bend, powder concentrator’s inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine, coal hopper, coal feeder, orifice |

| Ball mill system | Separator’s pipe, elbow and cone, coal mill’s elbow and straight tube | |

| Medium-speed mill | coal mill body, separation buffles, cone, pipeline, elbow | |

| Fall mill | Pulverized coal’s pipeline and elbow | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Ash discharge system | Fan duster’s shell, pipeline | |

| Port | Transporting material system | Bucket wheel machine’s disk and hopper, transfer point’s hopper, unloader’s hopper, |

| Smelting | Transporting material system | Measuring hopper, coke hopper, vibrating screen’s chute, head valve, Intermediate bin, tail bin |

| Batching system | batch hopper, mixing machine | |

| Burning system | Ash bucket, pump calcine tube, hopper | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Chemical | Transporting material system | Hopper, silo |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine, coal hopper, coal feeder |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper, silo |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Good quality Alumina Oxide Cylinders - Engineering Ceramic Tile Liner – Chemshun , The product will supply to all over the world, such as: Cape Town, Auckland, Israel, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Write your message here and send it to us