Manufacturer for Cutting Tile Liner - ZTA Rubber Ceramic Wear Liner – Chemshun

Manufacturer for Cutting Tile Liner - ZTA Rubber Ceramic Wear Liner – Chemshun Detail:

Feature

Higher strength than alumina

Lower cost than zirconia

Exceptional wear resistance

High corrosion resistance

High fracture toughness

High temperature stability

Advantage

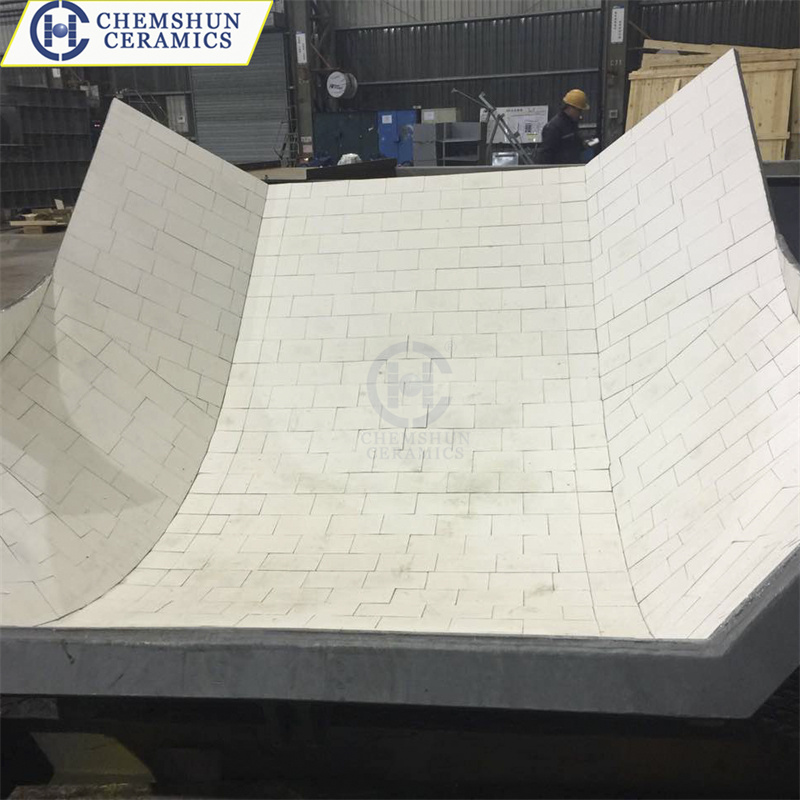

Wear resistant rubber ceramic liners are used to offer higher wear and impact protection.

1) Combine energy absorbing rubber and excellent abrasion resistant high alumina ceramic, suitable for high wear and impact applications.

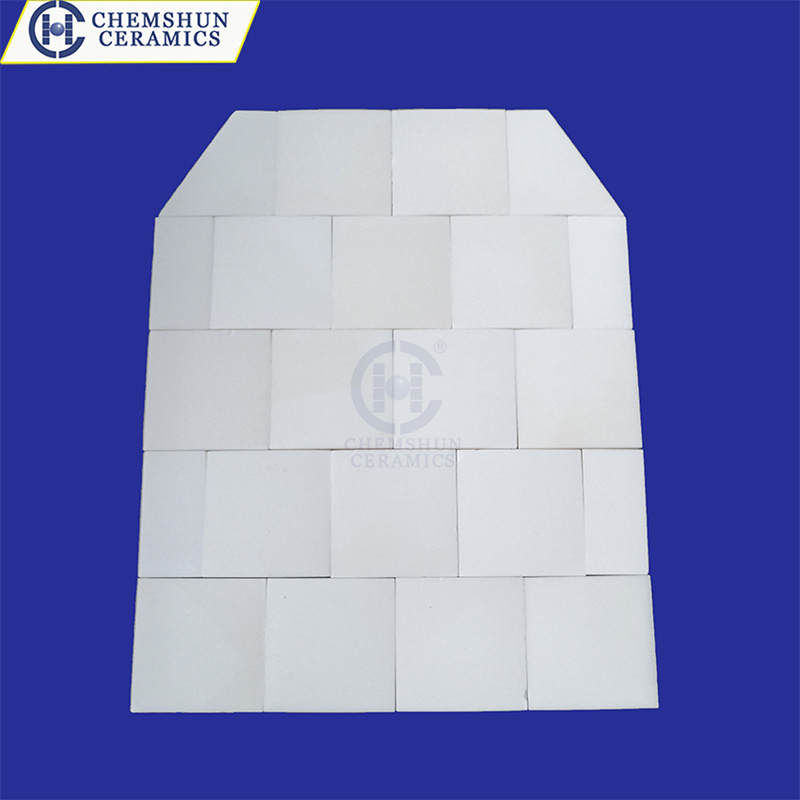

2) Custom shape and size to meet your specific requirements, standard liners and non-standard ones are all available.

3) Complete wear and abrasion solutions

4) Manufacturer with rich experience, good bond between rubber and ceramic, ceramics stay in place until completely worn.

5) Wide range of rubber ceramic wear plates to meet your different requirements.

Application

1)Bunker

2)Feed chute

3)Discharge chute

4)Ore storage

5)Hopper

6)Bin

Technical Data Sheet

|

PART |

PROPERTIES |

UNIT |

ZTA Ceramic |

|

Ceramic |

Al2O3 |

% |

70-75 |

|

ZrO2 |

% |

25-30 |

|

|

Density |

g/cm3 |

4.20 |

|

|

Vickers hardness |

Kg/mm2 |

1300 |

|

|

Fracture toughness |

Mpa.M1/2 |

3-4 |

|

|

Rubber |

Flexural strength |

Mpa |

680 |

|

Composition |

- |

Nature rubber+SBR |

|

|

Shore hardness |

HA |

60±5 |

|

|

Tensile elongation rate |

% |

>400 |

|

|

Tensile strength |

Mpa |

25 |

|

|

Tear strength(%) |

% |

30 |

|

|

Bonding strength between rubber and ceramic |

Mpa |

4 |

|

|

Steel |

Material |

- |

Q235A |

|

Tensile strength Density |

g/cm3 |

7.85 |

|

|

Thickness |

mm |

5-6 |

|

|

Adhesive |

Appearance |

- |

Brown glutinous liquid |

|

Solid content |

- |

20±3% |

|

|

Viscosity |

Mpa |

≥2.5 |

|

|

Peel strength |

48h N/2.5cm |

≥120 |

|

|

Compressive strength |

Mpa |

≥850 |

|

|

Working temperature |

ºC |

-20 – 100 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Manufacturer for Cutting Tile Liner - ZTA Rubber Ceramic Wear Liner – Chemshun , The product will supply to all over the world, such as: Kenya, Seattle, Wellington, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.