New Fashion Design for Disc Wafer Round Substrate - Alumina Ceramic Lined Pipe Equipment – Chemshun

New Fashion Design for Disc Wafer Round Substrate - Alumina Ceramic Lined Pipe Equipment – Chemshun Detail:

Product Description

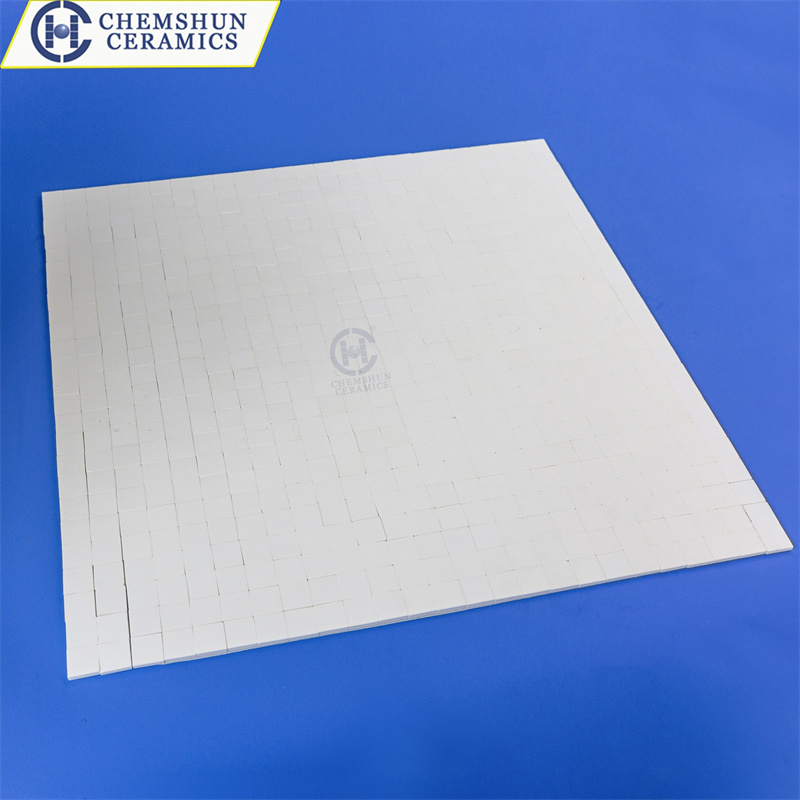

| Product Name | Alumina Ceramic Tile for Lining Pipe |

| Size | 150×53/49.38x13mm, 150×53/49x25mm,150×50/46x25mm,100×35/32x13mm |

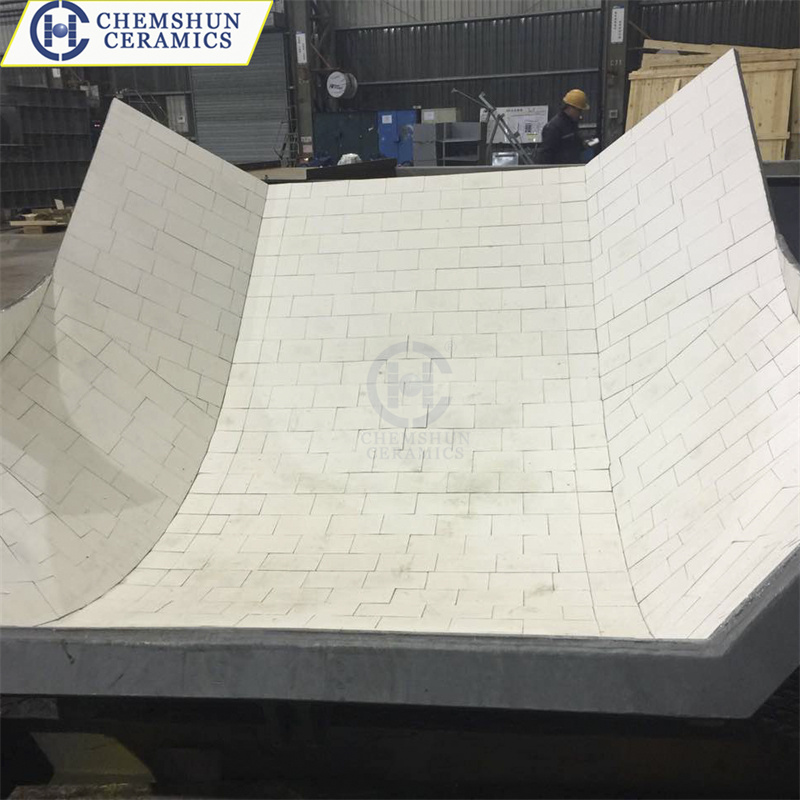

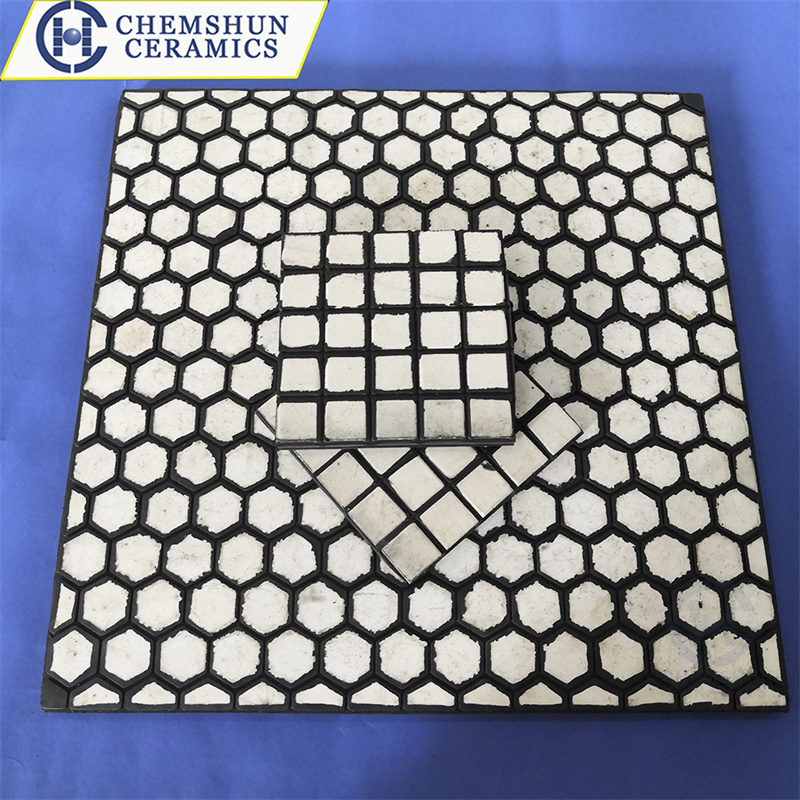

| Description | Chemshun Alumina Ceramic Tile for Lining Pipe is also called Alumina Ceramic Pipe Tile. It is used with advantage of the trapezoidal-shape and the benefit feature of the alumina Ceramic in lining steel pipe to avoid corrosion and abrasion. And then reduce the maintenance cost and prolong the use life of the pipes. |

| Feature | 1.High purity; 2.High hardness; 3.Simple shape |

| Benefit | 1.Excellent anti-resistant and corrosion resistance; 2.Excellent anti-impact; 3.Easy to pack and installation for using due to the simple shape and this could reduce the time cost; 4.Its abrasion is 266 times than that of manganese, 171.5 times to high chrome cast iron. |

| Application | 1.Used to be line in steel pipe |

| Related Industry | Steel plant, power plant, refinery factory, cement plant, mining industry, port industry,etc. |

| Facilities for lining | Chute, hopper, bunker, stacker, Belt conveyor, Coal feeder, Distributor, Pipe and elbow, Burner, Valve |

Specification

| Technical | Unit | 92AL | 95AL |

| Alumina | % | 92 | 95 |

| Density | g/cc | 3.60 | 3.68 |

| Flexural Strenght | Mpa | 275 | 300 |

| Rock well hardness | R45N | 75 | 78 |

| Vickers Hardness (HV10) | Kg/mm2 | 1050 | 1120 |

| Fracture Toughness | Mpa.m1/2 | 3-4 | 4-5 |

| Thermal Expansion Coefficient(25-1000ºC) | 1X10-6/ºC | 8.0 | 8.1 |

| Max. Use Temp. | ºC | 1250 | 1250 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for New Fashion Design for Disc Wafer Round Substrate - Alumina Ceramic Lined Pipe Equipment – Chemshun , The product will supply to all over the world, such as: French, Jakarta, Canada, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us