In the mining, metallurgy, power and other industries, the chute is a key equipment for material transportation, and its wear resistance is directly related to production efficiency and equipment life. Faced with the impact and friction of high-speed flowing materials, abrasion resistant ceramics have become an ideal choice for protecting the chute from wear with their excellent performance.

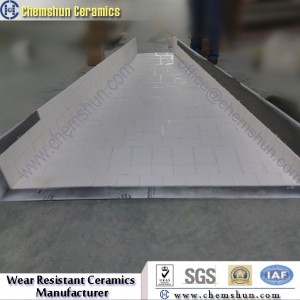

Wear resistant ceramics, known for their high hardness, high strength and excellent wear resistance, can effectively resist the erosion and wear of materials. Abrasion resistant ceramic materials are applied to the inner wall of the chute by attachment, inlay or integral casting to form a solid protective layer. This protective layer can not only effectively reduce the direct impact of materials on the chute, but also form a buffer zone between the material and the chute to reduce the wear caused by friction.

In addition, abrasion resistant ceramic materials also have good corrosion resistance, can operate stably for a long time under harsh working conditions, and are not damaged by corrosive substances such as acids and alkalis. This feature further extends the service life of the chute and reduces maintenance costs.

In summary, wear resistant ceramics provide all-round protection for the chute with their excellent wear resistance and corrosion resistance. By applying wear-resistant ceramic materials, we can effectively prevent performance degradation and equipment failure caused by wear of the chute, ensuring the continuous and stable operation of the production line. Chemshun Ceramics manufacturer can solve you all wear damage problem with ceramic chute liner . welcome to inquire us by office@chemshun.com

Post time: Oct-25-2024