What is the most resistant material? When it comes to materials that can withstand wear and tear, there are a few options that come to mind. Two common materials used for abrasion resistant applications are alumina ceramics and silicon carbide ceramics.

Alumina ceramics, also known as aluminum oxide, are a type of ceramic that is highly resistant to wear and tear. This material is composed of aluminum oxide, which has high levels of hardness and toughness. Alumina ceramics are commonly used as abrasion resistant materials in a variety of industries, including mining, cement, and power generation.

Another type of ceramic that is commonly used for abrasion resistant applications is silicon carbide ceramics. Silicon carbide is a material that is composed of silicon and carbon, and is known for its hardness and resistance to wear and tear. Silicon carbide ceramics are used in industries such as automotive and aerospace, as well as in the production of cutting tools and abrasive materials.

When it comes to choosing between alumina ceramics and silicon carbide ceramics for abrasion resistant applications, it is important to consider the specific requirements of the application. While both materials are highly resistant to wear and tear, they have different properties that may make one more suitable for a particular application than the other.

For example, alumina ceramics are known for their high chemical resistance and thermal stability. This makes them ideal for use in applications where exposure to harsh chemicals or high temperatures is a concern. On the other hand, silicon carbide ceramics are known for their high strength and hardness, which makes them suitable for applications where high levels of abrasion resistance are required.

One application where abrasion resistant materials are commonly used is in the lining of chutes. Chutes are used to transport materials from one location to another, and are often subject to wear and tear due to the abrasive nature of the materials being transported. In order to prevent damage to the chute and ensure a long service life, it is important to use a material that can withstand the abrasion.

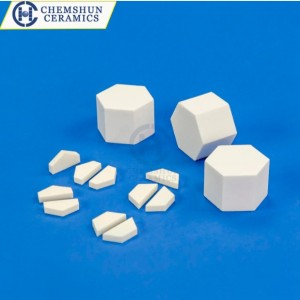

Chemshun Ceramics-Ceramic chute liners are an excellent choice for applications where abrasion resistance is required. Alumina ceramics and silicon carbide ceramics are both commonly used for chute liners due to their high levels of abrasion resistance. In addition to their resistance to wear and tear, ceramic chute liners are also known for their ability to reduce noise and vibration, which can be beneficial in certain applications.

In conclusion, when it comes to abrasion resistant materials, alumina ceramics and silicon carbide ceramics are two of the most common options. Both materials are highly resistant to wear and tear, but have different properties that may make one more suitable for a particular application than the other. Ceramic chute liners are an excellent application for both types of ceramics, as they are able to withstand the abrasive nature of the materials being transported while also reducing noise and vibration.

Post time: Jun-15-2023