Alumina ceramic is an important inorganic non-metallic material, which has the advantages of high strength, high hardness, corrosion resistance, impact resistance, high temperature resistance and so on. In industry, alumina ceramics are widely used in thermal power, mining, coal, steel, cement and other industries.

Ceramic cylinders for hot vulcanization of composite lining are a common application. Alumina ceramics have excellent physical and chemical properties, especially high hardness, high temperature resistance, good insulation and other characteristics, so that it has a wide range of applications in many fields.

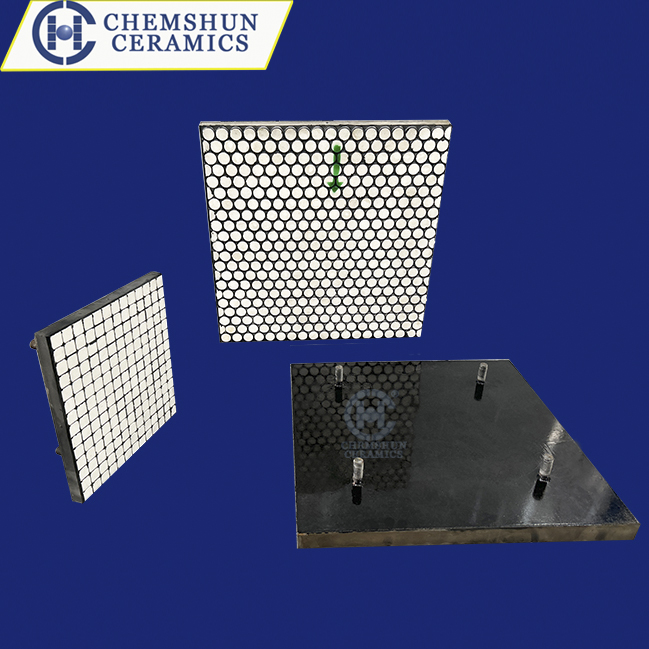

Hot vulcanized composite liner is a special type of liner, and the hot vulcanization process is to combine the two materials of wear-resistant ceramics and rubber together to make it a whole material. In this process, the alumina ceramic cylinder can play the role of support and support, making the entire lining structure more stable and durable.

Vulcanized plate is also known as ceramic rubber composite plate, in addition to the use of ceramic cylinders for vulcanization, you can also use ceramic lining plate, with high hardness and wear resistance. The rubber layer is located on the surface of the ceramic layer, which plays the role of cushioning, damping and sound absorption.

Ceramic rubber plate can be used for a variety of wear, impact and sound absorption occasions, such as chute, hopper, port and other wear places. It can also be used for many equipment, pipelines, valves and other parts that are in contact with corrosive media such as acid, alkali, salt, because it has certain anti-corrosion properties. In addition, the ceramic rubber composite board also has the advantages of convenient construction, good wear resistance, long service life and so on. During installation, it can be made into block, different shape, etc., and can be bonded or welded at the same time.

Post time: Jan-20-2025