In the thermal power industry, equipment is often damaged due to high temperature environment and high wear conditions, which affects the safety production of the entire system. In order to solve this problem, it is necessary to find materials that can withstand high temperatures and resist wear. Alumina ceramic materials are very suitable.

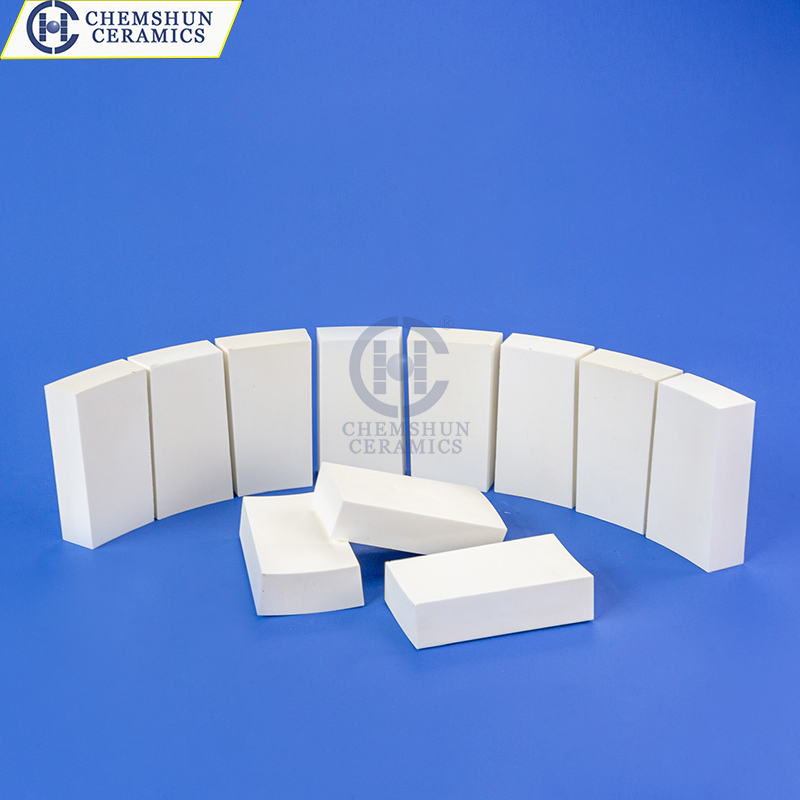

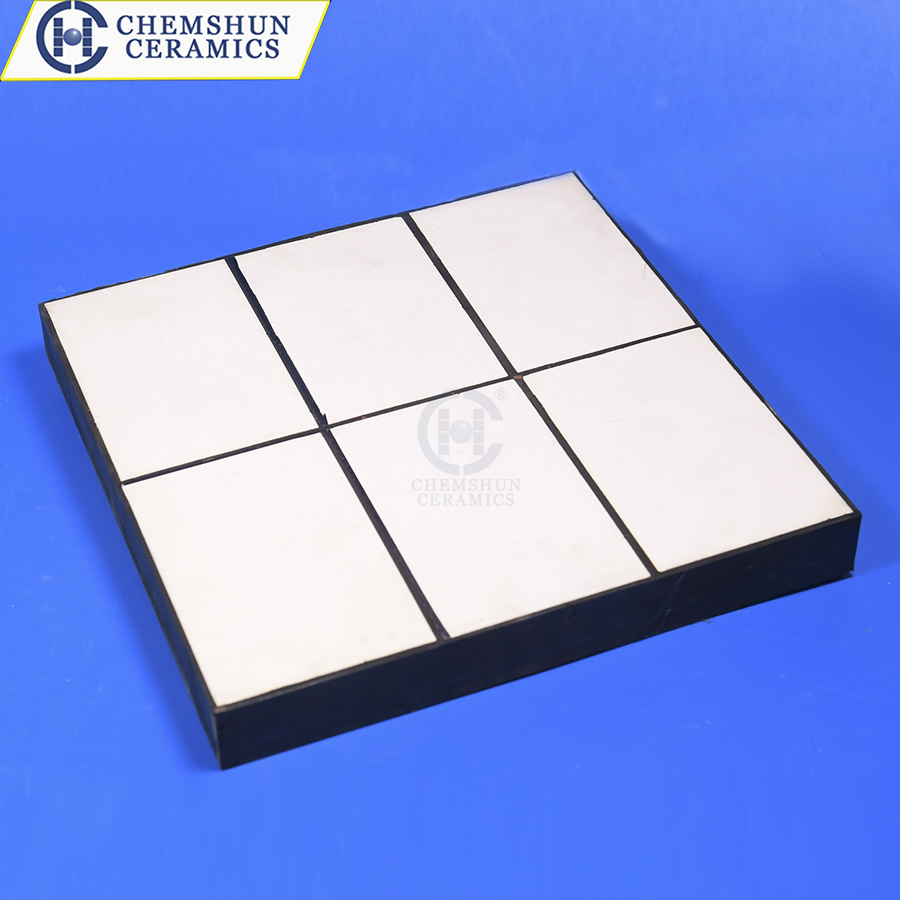

Alumina ceramic is a kind of alumina (Al2O3) as a raw material of ceramic material, after dry pressing, and then through more than 1,700 degrees of high temperature sintering. Alumina ceramics have the characteristics of good conductivity, mechanical strength, high temperature resistance and corrosion resistance. Measured by the Shanghai Institute of Silicate of the Chinese Academy of Sciences, its Rockwell hardness is HRA80-90, the hardness is second only to diamond, far more than the wear resistance of wear-resistant steel and stainless steel. The wear resistance is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our customer tracking survey for more than ten years, under the same working conditions, the service life of the equipment can be extended at least ten times.

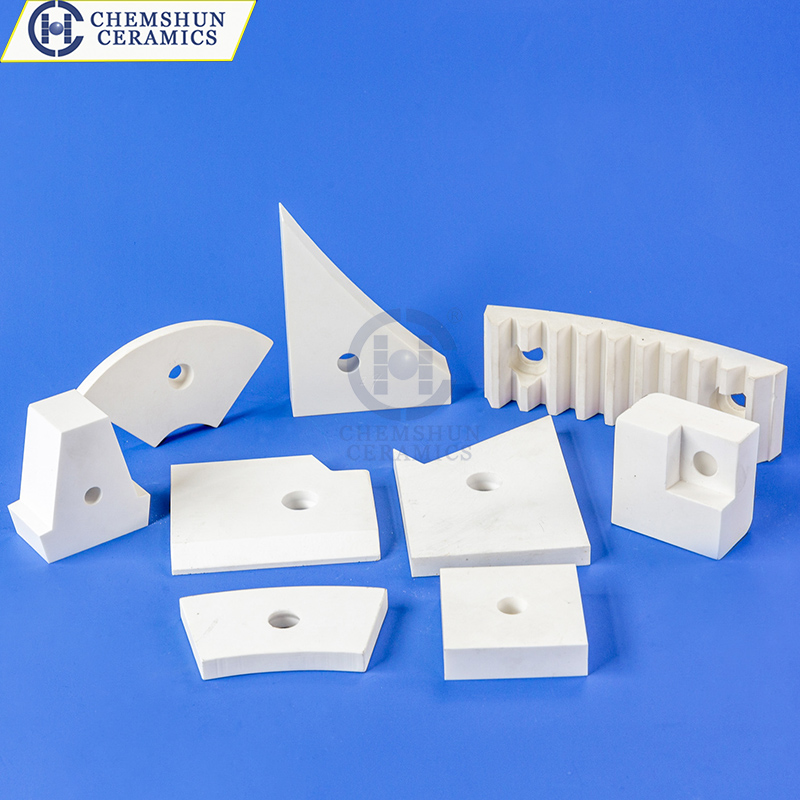

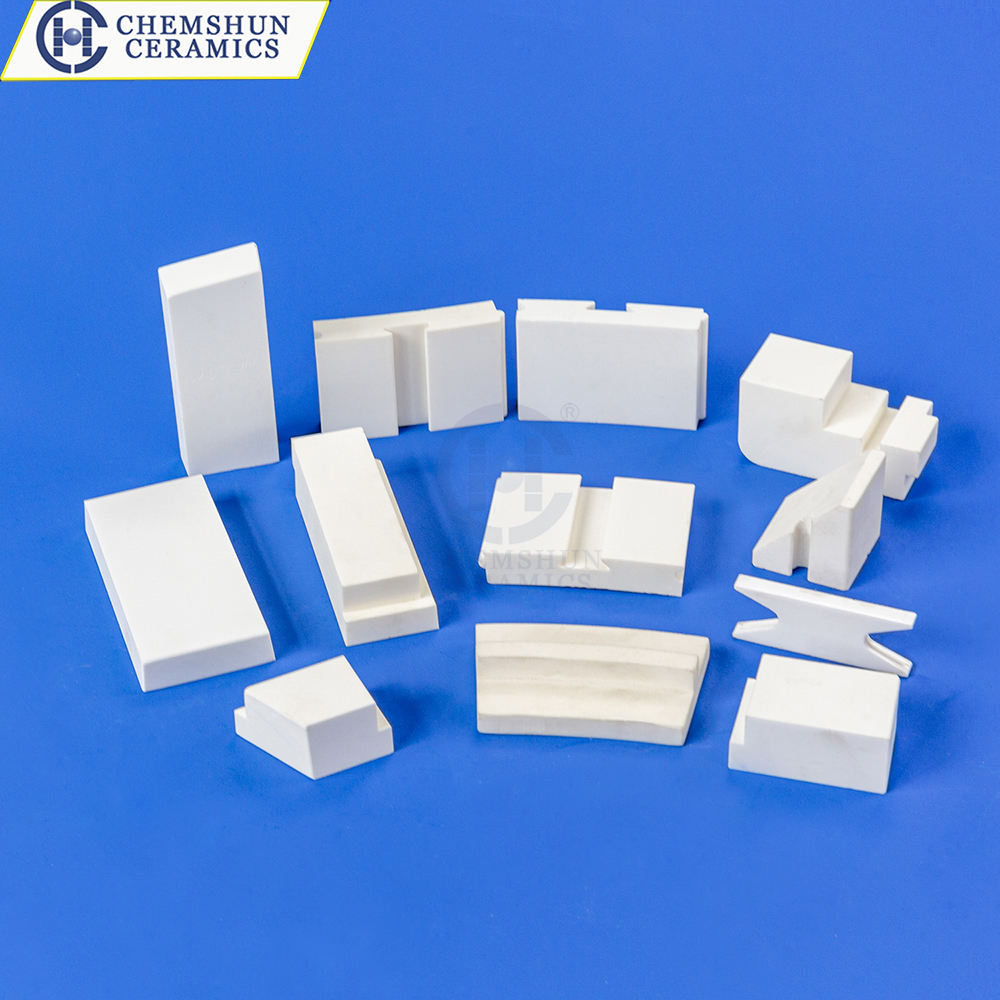

Alumina ceramics can be used in high-temperature and high-wear equipment components in the thermal power industry, such as fans, pump rotors, shells, pipes, seats, sealing rings, etc. These components need to withstand high temperature, high pressure and corrosive media, so they need to use good wear resistance materials to manufacture.

In the thermal power industry, the coal mill is the key equipment, and the application of wear-resistant ceramics can effectively improve the service life of the coal mill, and then ensure the operation of the entire boiler system. This can not only reduce the downtime of equipment failure, ensure the stable operation of the boiler system, but also reduce the cost of equipment maintenance, which is in line with the pursuit of economic benefits in the thermal power industry.

It should be noted that in practical applications, the specifications, content, processing and use of wear-resistant ceramics need to be selected according to the actual working conditions to ensure the best performance and results.

Post time: Apr-24-2024