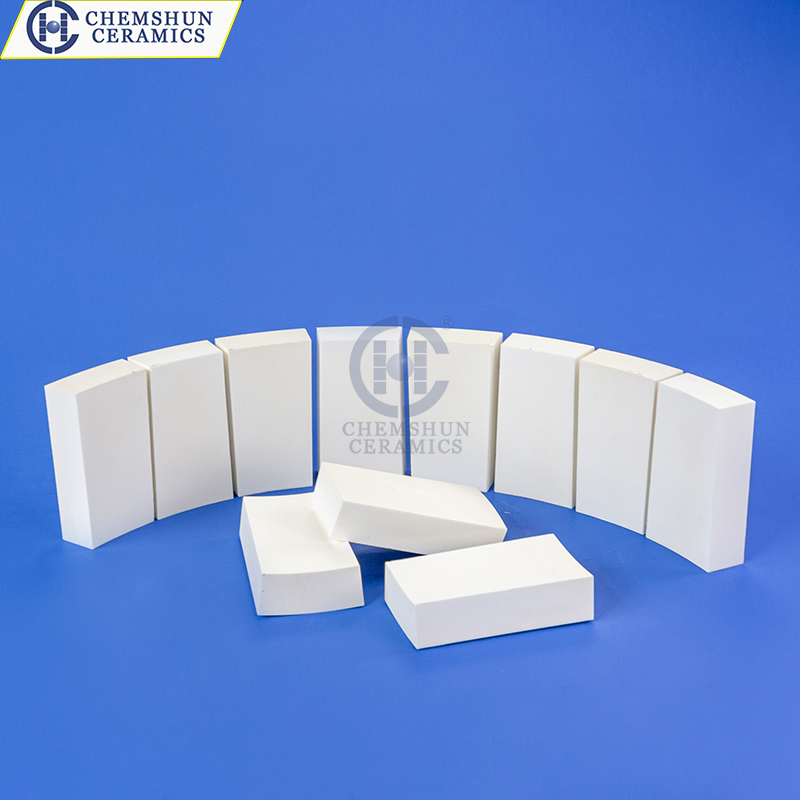

Alumina wear-resistant ceramics is a kind of alumina as the main material, because of its high hardness, super wear-resistant ability, has been widely used in the mining industry. Alumina wear-resistant ceramics have a high cost performance, easy to install, suitable for a variety of severe wear environment, is the mining industry to solve the equipment wear problem of the first choice material.

1. Wear-resistant parts in mining machinery

The application of alumina wear-resistant ceramics in mining machinery is mainly concentrated in wear-resistant lining plate, chute, pipeline and other components. In the mining conveying system, the mine chute, transfer station, hopper and so on are subjected to the impact wear of large ores for a long time, and the edges of the ores are sharp and the cutting wear is serious. The use of alumina wear-resistant ceramics can significantly improve the wear resistance and service life of these components and reduce maintenance costs.

2. Ore crushing and screening equipment

In the process of ore crushing, alumina wear-resistant ceramics can be used to make parts such as crushing hammer and lining plate. These components can significantly improve the crushing efficiency and yield when crushing ore, in addition, the screen made of alumina wear-resistant ceramics can improve the screening efficiency and accuracy, and reduce the occurrence of plugging phenomenon.

3. Mine piping system and valves

Alumina wear-resistant ceramics are also widely used in mine pipeline systems and valves. In the mine conveying system, wear-resistant ceramic pipes and elbows and other components can reduce the wear and corrosion of materials on the pipeline and extend the service life of the pipeline. At the same time, wear-resistant ceramic valves and other components can improve its sealing performance and durability to ensure the stable operation of the system.

4. Mine environmental protection facilities

In the mine waste gas treatment and tailings treatment, alumina wear-resistant ceramics also play an important role. Parts such as tailings pumps and pipes made of wear-resistant ceramics can improve the efficiency and safety of tailings transportation. In waste gas treatment, wear-resistant ceramics are lined with parts such as dust removal equipment and desulfurization and denitrification devices, which can improve the corrosion resistance and stability of the equipment and ensure the efficient operation of environmental protection facilities.

Alumina wear-resistant ceramics are widely used and important in mining industry. Its high hardness, wear resistance and chemical stability make it the preferred material for wear parts of mining equipment. Through the use of alumina wear-resistant ceramics made of anti-wear lining, chute, pipeline, crushing hammer, screen and other components, mining enterprises can significantly improve the wear resistance and service life of equipment, reduce maintenance costs, improve production efficiency and economic benefits. In the future, with the development of the mining industry and the progress of technology, the application of alumina wear-resistant ceramics in the mining industry will be more extensive and in-depth.

Post time: Nov-11-2024