A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Ball mill is widely used in mining, metallurgy, chemical industry and other industries. However, the long-term use of the ball mill often leads to the wear of the inner wall of the equipment, which affects the production efficiency. To solve this problem, we can install wear-resistant ceramic liner on the inner wall of the machine.

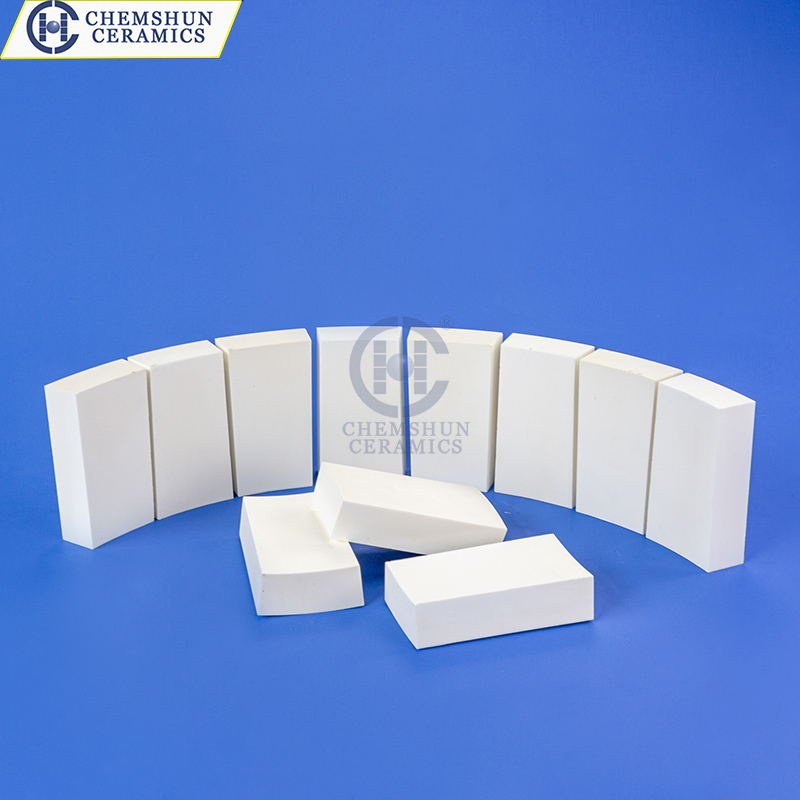

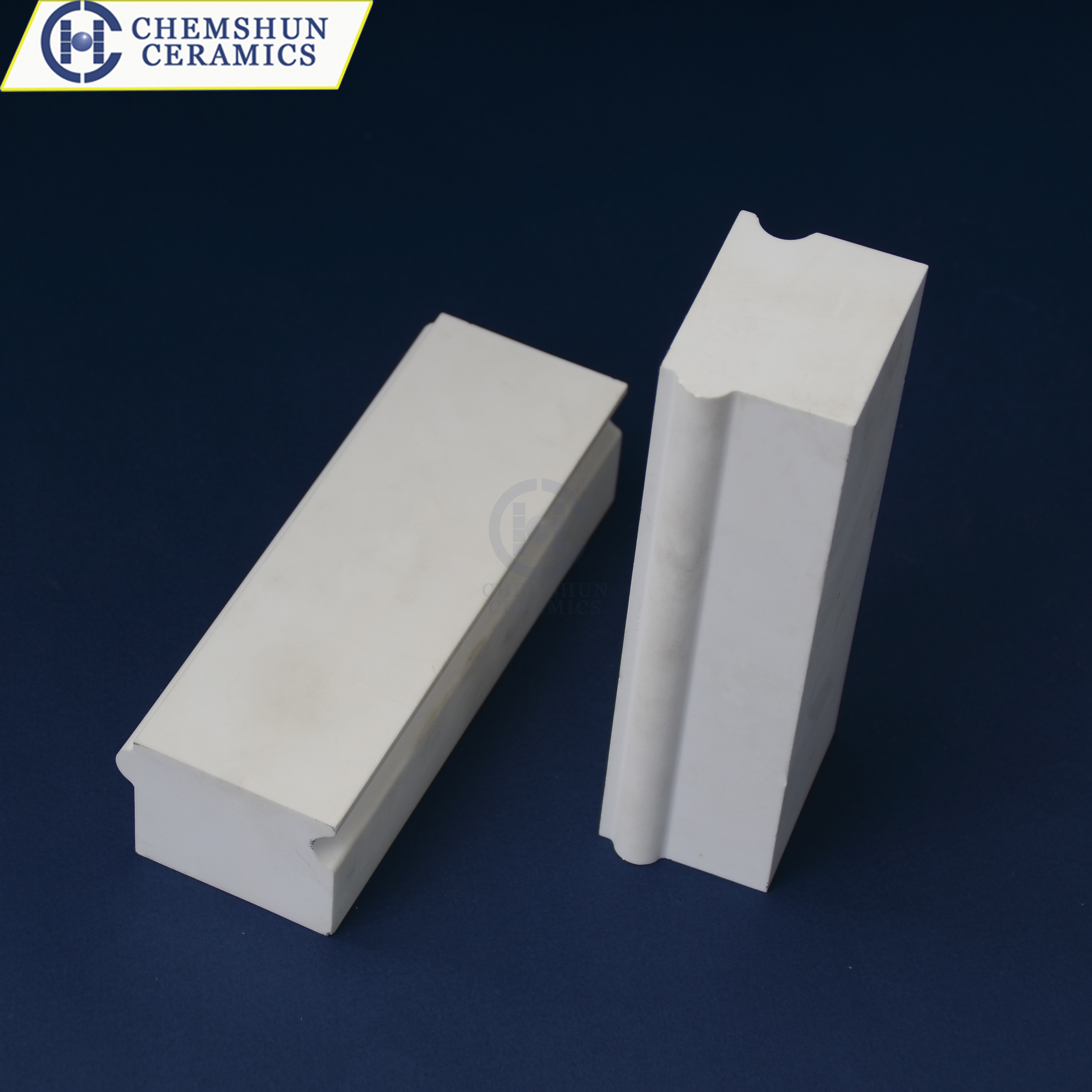

1.The structure and characteristics of wear-resistant ceramic liner

Wear-resistant ceramic liner is made of high hardness ceramic material by special process, with high hardness, corrosion resistance, high temperature resistance. The hardness of wear-resistant ceramic liner is generally above 9, much higher than that of ordinary steel, and its coefficient of friction is relatively low, which can effectively reduce wear. Wear-resistant ceramic liner has good stability in corrosive media and can resist the erosion of chemical substances such as acid and alkali. Wear-resistant ceramic lining can still maintain good performance at high temperature, is not easy to deform, and is not affected by thermal expansion and contraction. Wear-resistant ceramic liner is lighter than ordinary steel, which can reduce the burden of equipment and reduce energy consumption.

2. The advantages of wear-resistant ceramic liner used in ball mills

Reduce friction: The high hardness and low friction coefficient of the wear-resistant ceramic liner can reduce the friction between the liner and the grinding body, thereby reducing energy loss and improving the efficiency of the ball mill.

Increase service life: wear-resistant ceramic liner has excellent wear resistance, which can effectively extend the service life of the ball mill, reduce the frequency of consumable replacement, and reduce maintenance costs.

Promote material grinding: wear-resistant ceramic liner has a small friction coefficient, which can reduce the temperature rise of the material during the grinding process, reduce the adhesion of the grinding material, and improve the grinding effect.

Conclusion: wear-resistant ceramic liner, as an important part of ball mill, plays an important role in ball mill process. Its structure and characteristics make it have high hardness, wear resistance and corrosion resistance, which can effectively reduce wear and improve the efficiency and service life of the ball mill. With the continuous development of technology, the application prospect of wear-resistant ceramic liner in ball mill will be more broad.

Post time: Jun-17-2024