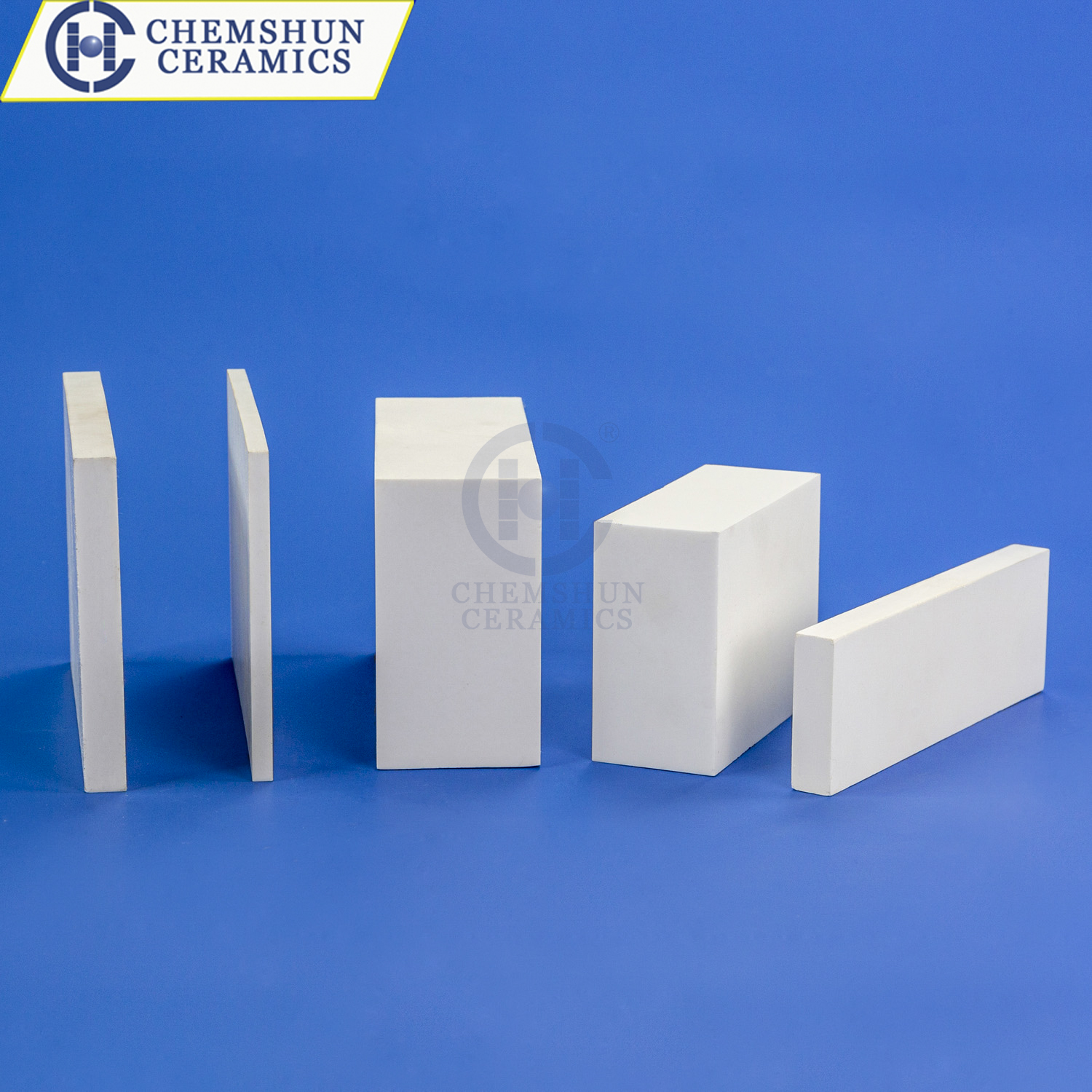

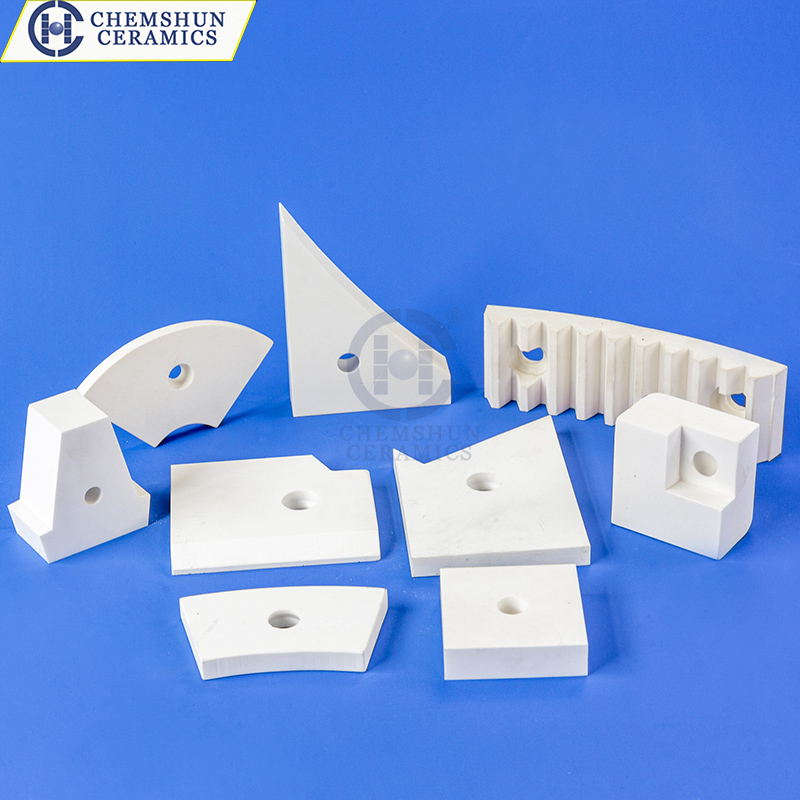

Wear-resistant ceramics are widely used in cement industry. The main advantages of wear-resistant ceramics include wear resistance, corrosion resistance, high temperature stability, high temperature oxidation resistance and good mechanical strength. The following are some of the main application areas in the cement industry:

1. Crusher: wear-resistant ceramics can be used in the lining of the crusher to extend its service life and reduce wear.

2. Grinding body: wear-resistant ceramic ball can be used in cement mill, mine mill grinding body, improve grinding efficiency.

3. Wear-resistant skid parts: wear-resistant ceramic pieces can be used for wear-resistant skid parts in conveying equipment.

4. Fan: wear-resistant ceramics can be used for the lining of fan blades and wind shells to enhance their wear resistance.

5. High wear-resistant pipes for mining: wear-resistant ceramics and steel pipes made of ceramic composite pipes, with high wear-resistant properties, to replace the traditional cast stone and alloy pipes.

6. Cement kiln head cover wear parts: Due to serious material wear in the cement production process, the service life of the kiln head cover wear parts is the key. Wear-resistant ceramic coating or wear-resistant ceramic liner can be used for modification of kiln head cover.

7. Lower support wheel of rotary kiln: the lower support wheel of rotary kiln is in a high temperature state for a long time, easy to produce thermal deformation, and the use of wear-resistant ceramic materials can improve the service life.

It can be seen from the above applications that the application of wear-resistant ceramics in the cement industry mainly solves some important equipment wear problems, improves the efficiency and service life of the equipment, and thus reduces the production cost. However, please note that in the specific use of wear-resistant ceramics, appropriate materials and processes should be selected according to the actual situation, and appropriate maintenance and management.

Post time: Jan-19-2024