In today’s special international environment, Bulletproof plate(or bulletproof tiles) are highly valued by people, but on the market of bulletproof plate is multifarious, performance difference is very big also, according to the material, process and other common bulletproof plate can be divided into three categories, namely steel bulletproof plate, polyethylene PE bulletproof plate and ceramic bulletproof plate, the three kinds of bulletproof plate each have advantages and disadvantages, The choice also requires comprehensive consideration. Choose bulletproof plate, need to focus on the three attributes are weight, price and bulletproof ability (namely bulletproof level), today we are from these three aspects of the three kinds of bulletproof plate analysis and comparison.

1. Steel bulletproof plate

Steel bulletproof plate have been in use since World War II and dominated the bulletproof market decades ago. But after the development of polyethylene PE bulletproof plate and ceramic bulletproof plate, steel bulletproof plate was gradually replaced. They are still used today, but in smaller numbers.

Compared with the new bulletproof plate, the steel bulletproof plate is easy to break after being shot, which will cause secondary damage to the human body. Compared with the other two materials, the steel bulletproof plate with the same level of protection is heavier, consumes more energy and reduces the flexibility of the wearer.

Although the steel bulletproof plate is the lowest price in the three inserts, but overall, it is not recommended as the first choice.

2. Polyethylene PE bulletproof plate

Polyethylene PE is a new type of thermoplastic material. Polyethylene PE bulletproof plate is manufactured by bonding unidirectional ultra-high molecular weight polyethylene fibers onto a high-density polyethylene board. It is cut into shape, placed in a mold, and compressed under high temperature and pressure to obtain a viscous hard armor plate. The polyethylene “sticks” to the bullet by melting the polyethylene due to friction caused by the bullet’s rotation. When the rotation stops, no heat is generated, and the polyethylene cools and re-hardens.

The quality of polyethylene PE bulletproof plate is generally about 1 to 1.5kg, much lighter than steel bulletproof plate and ceramic bulletproof plate. However, due to the limitations of the current material process, pure PE plate can achieve the highest protection level of NIJ III, unable to defend against rifle piercing bullets and more powerful bullets, and the high cost of polyethylene PE, its price is often 200% to 300% more expensive than ceramic bulletproof plate, is not a good choice.

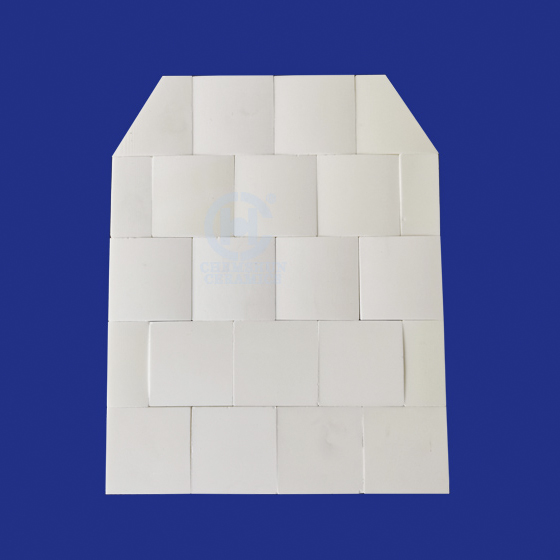

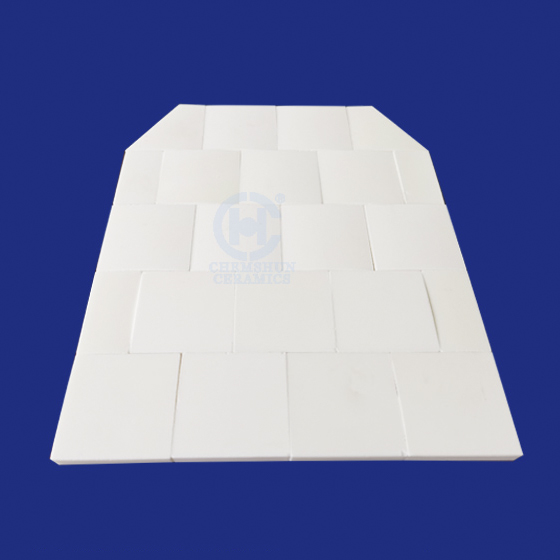

3. Ceramic bulletproof plate

Ceramic inserts can use a variety of materials, more common are alumina, silicon carbide and boron carbide. Ceramics are bulletproof because of their high specific stiffness, strength, and chemical inertness in many environments. It is better than metal because metal materials will produce plastic deformation and absorb energy when resisting the impact of the warhead, while ceramic will hardly produce plastic deformation and the warhead will be blunt or even broken due to its own high strength and hardness characteristics. Bulletproof ceramic and high strength high modulus fiber composite plate bulletproof layer, when the high-speed projectile and the ceramic layer collision, the ceramic layer fragmentation or crack and to the impact point as the center to the surrounding to consume most of the energy of the projectile body, then the high modulus fiber composite plate to further consume the residual energy of the projectile body. Therefore, the application of advanced ceramics in armor systems is very attractive and has become a widely used protective armor for body armor, vehicles, aircraft and other equipment.

The disadvantage of ceramic plate is that after being hit, the impact point cannot defend the bullet again. But now the ceramic plate is lighter and stronger than before, some manufacturers can even make its weight close to PE plate, and through the use of different materials can also meet the weight, price and other requirements.

In the same size with the same level of protection, ceramic bulletproof plate is lighter than steel bulletproof plate, and the price is lower than polyethylene PE plate and even the thickness can be thinner.

In general, the steel bulletproof plate is simple and low price, but the weight is too large, and easy to cause secondary damage to the user; Although the polyethylene PE bulletproof plate is light, but the bulletproof ability is poor, and the price is expensive; Comparatively speaking, ceramic bulletproof plate not only light quality, low price, and bulletproof ability is excellent; The performance of silicon carbide ceramic bulletproof plate is more on the alumina plate, is the best choice of bulletproof plate.

Post time: Sep-26-2022