Ceramic tile liners are widely used in industries that involve heavy wear and tear, such as mining, construction, and manufacturing. These liners are made of highly durable materials like alumina ceramic, which is a type of advanced ceramics that is known for its excellent wear resistance, chemical inertness, and high-temperature stability.

Despite their toughness, however, ceramic tile liners can still be subject to damage and wear over time, particularly in high-stress areas. In some cases, it may be necessary to cut ceramics to fit a specific application or repair damaged liners. This can be a challenging task, but with the right tools and techniques, it is possible to achieve precise cuts on even the hardest materials.

To cut wear-resistant ceramic tile liners, you will need a few specialized tools, including a diamond blade or saw, a cutting wheel, and a water cooling system. These tools will help you to make clean, accurate cuts without damaging the material or compromising its durability.

Before you begin cutting, it is important to measure and mark the area where the alumina liner needs to be trimmed or shaped. This will help you to ensure that your cuts are precise and that the liner fits perfectly in the desired location. Once you have marked the area, you can use the diamond blade or saw to cut the ceramic tile liner, using a slow, steady motion to minimize dust and ensure a smooth cut.

It is also important to use a water cooling system during the cutting process, as this will help to prevent the ceramic tile liner from overheating and cracking. The water will also provide lubrication and keep the blade or wheel cool, ensuring that it stays sharp and effective.

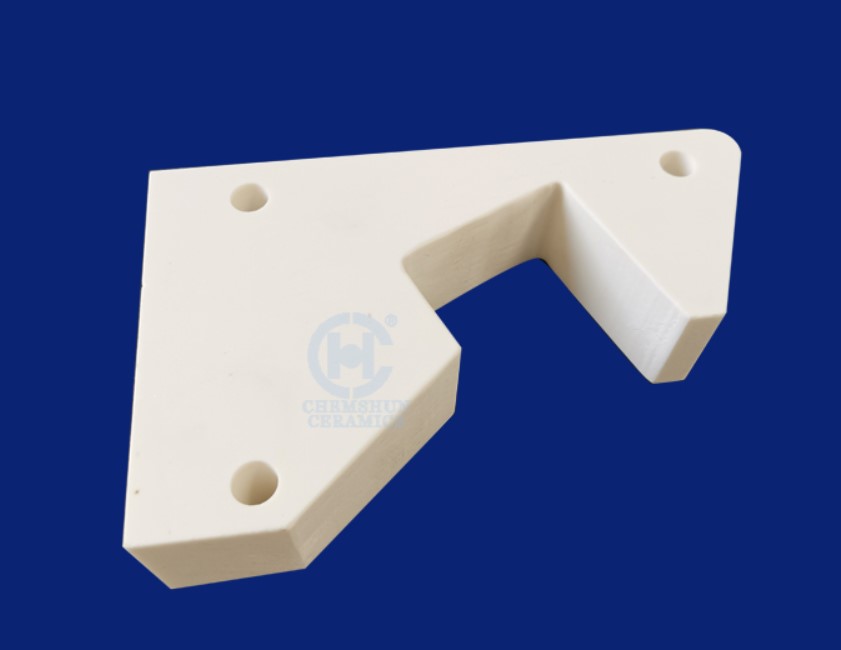

Customized ceramics can also be created via cutting. Many manufacturers specialize in creating bespoke or customized ceramics, which can be tailored to specific requirements. This could involve cutting ceramic tile liners into unique shapes or designs, or using other advanced ceramic materials to create customized products that offer the ideal combination of durability, performance, and aesthetics.

Overall, Chemshun Ceramic cutting wear-resistant ceramic tile liners can be a complex process that requires careful planning, the right tools, and an understanding of the unique properties and characteristics of advanced ceramic materials. However, with the right approach, it is possible to achieve precision cuts that meet the highest standards of quality and durability, and ensure the longevity and performance of your ceramic tile liners in even the toughest industrial environments.

Post time: May-13-2023