Wear resistant ceramic pipes are made of alumina ceramics, special ceramic glue, and steel pipes. Alumina ceramics, as a protective layer inside the steel pipe, have a high wear resistance. The service life of wear-resistant ceramic pipes is several times higher than that of general wear-resistant pipes. They are widely used in lithium batteries, steel, cement, and coal transportation pipelines.

There are several different lining construction processes for blind-resistant ceramic pipes.

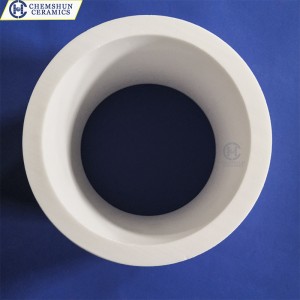

The first is the lined alumina ceramic pipe. The ceramic pipe is sintered after isostatic pressing and installed in the steel pipe in sections. The inner wall is smooth, with few steps and few seams, which reduces the resistance of material transportation. It is suitable for pneumatic transportation industries such as lithium batteries and thermal power industries.

The second is the patch-type ceramic pipe, which uses ceramic sheets or ceramic linings and is pasted in the pipe. This construction is more complicated and requires professional construction technology.

The third is the welded ceramic pipe, which uses a ceramic lining with holes. After the glue is pasted on the lining, the iron sheet is welded in the steel pipe through the small holes, and finally the ceramic cover is sealed to protect the welding points. Welded ceramic pipes are suitable for conveying conditions with strong impact. The double fixing process can resist the impact and friction of materials. Therefore, welded ceramic pipes are suitable for making chutes, silos and hoppers.

Post time: Aug-19-2024