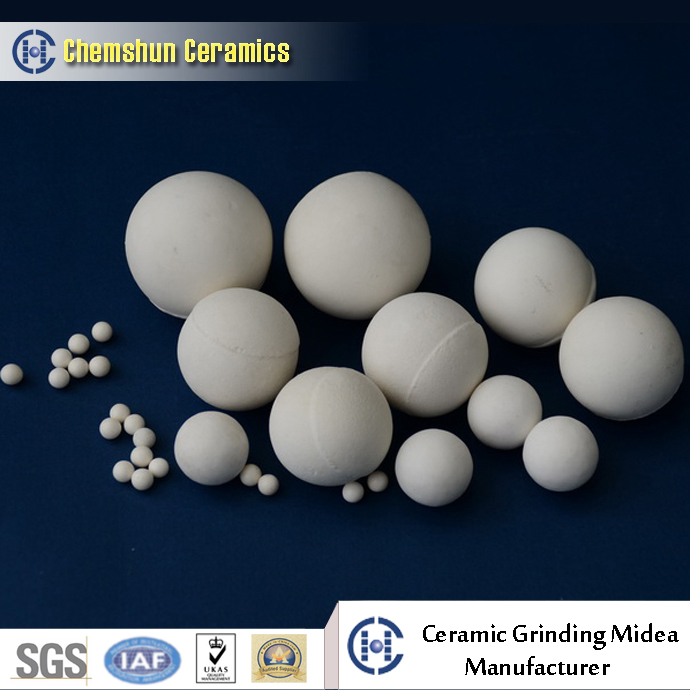

Alumina ceramic balls are spheres made of alumina, ranging in size from microbeads to large balls. It is generally white, with high hardness and high wear resistance, widely used in cement, quartz sand, metal ore, paint, ink and other industries, as a support, isolation and grinding material.

Alumina ceramic ball has many advantages, such as wear resistance, high hardness, good thermal stability, chemical stability and so on. However, its density is small, toughness is not high, and it is easy to crack and crack under certain pressure and temperature. Therefore, in the process of use, it is necessary to take into account the impact of these factors on the performance of alumina ceramic balls.

In industrial applications, alumina ceramic balls can be used to grind various materials, such as ceramics, glass, metals, plastics, etc., to achieve the purpose of fine grinding, fine grinding, dispersion and catalyst carriers.

Alumina ceramic balls need to correctly select factors such as particle size, hardness, shape and so on when used to ensure the grinding effect and the safe operation of the equipment. At the same time, it is necessary to control the grinding time and temperature during use to avoid damage to the equipment.

Alumina ceramic ball is an important grinding medium, because the alumina ceramic ball has high hardness, high wear resistance, corrosion resistance and other characteristics, so it can effectively improve the grinding efficiency and quality. It is widely used in cement industry, quartz sand, metal ore and other industrial fields.

Post time: Apr-16-2024