In the industrial production process, the feed chute is an important component to undertake material transportation, and its wear resistance and impact resistance will directly affect whether the production can run stably. Traditional wear-resistant materials because the wear resistance is not strong enough, often after a period of use will appear serious wear phenomenon, resulting in material leakage and equipment failure, so that production efficiency is reduced, the frequency of downtime and maintenance is increased, and business operating costs are also increased.

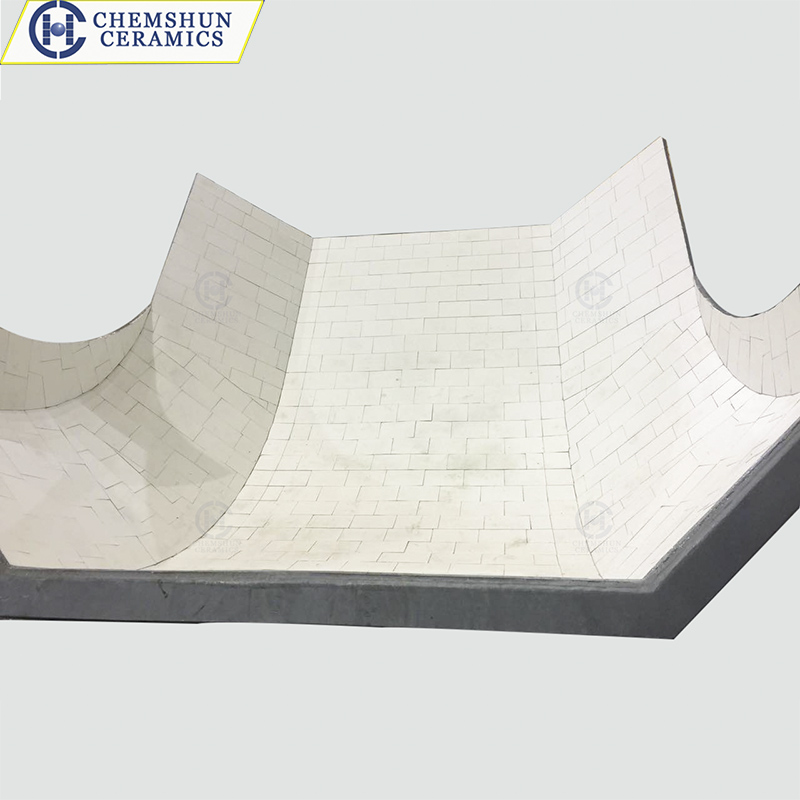

In order to solve this problem, the use of wear-resistant ceramic materials for anti-wear treatment of the feed chute has become the preferred solution in the industry. Wear-resistant ceramics exhibit exceptional durability under harsh conditions due to their excellent hardness, good impact resistance and extremely low wear rate. Through the tight bonding technology, the wear-resistant ceramic liner is firmly installed on the inner wall of the chute, forming a solid protective barrier, effectively resisting material erosion and friction, and greatly extending the service life of the chute.

Practical application cases show that the wear resistance of the feed chute pasted with wear-resistant ceramics is significantly improved, and the wear rate is reduced by at least 50%, and even more than 80% in some cases, compared with the chute without wear-resistant ceramics. This not only means fewer equipment replacements and repairs due to wear and tear, but also significantly improves production continuity and efficiency.

In addition, wear-resistant ceramics have good chemical stability and can withstand the erosion of a variety of corrosive materials, which further broadens the application range of the feed chute, making it widely used in many industries such as chemical industry, mining, electric power, metallurgy and so on, and has obtained good user feedback.

In summary, the use of wear-resistant ceramics for anti-wear treatment of the feed chute not only significantly improves the wear resistance and service life of the equipment, reduces maintenance costs, but also effectively guarantees the stable operation of the production line and improves the overall economic benefits. This technological innovation has undoubtedly provided strong support for the efficient and sustainable development of modern industry.

Post time: Jan-15-2025