Abrasive Wear

Abrasive wear refers to the phenomenon that the surface of an object rubs against hard particles or hard projections (including hard metals), causing the loss of surface material. The abrasive wear mechanism is the mechanical action of the abrasive, which is largely related to the nature, shape and size of the abrasive, the degree of fixation, and the mechanical properties of the abrasive and the surface of the material to be ground under load.

The ways to minimize machine wear damage .

Bulk material handling system is typical of abrasive wear. Such as mine, port , steel plant, grinding system.bulk particles with different size delivered will cause chute, hopper, bin and other machines to work down. so it is most important to cut the abrasion wear for machines .

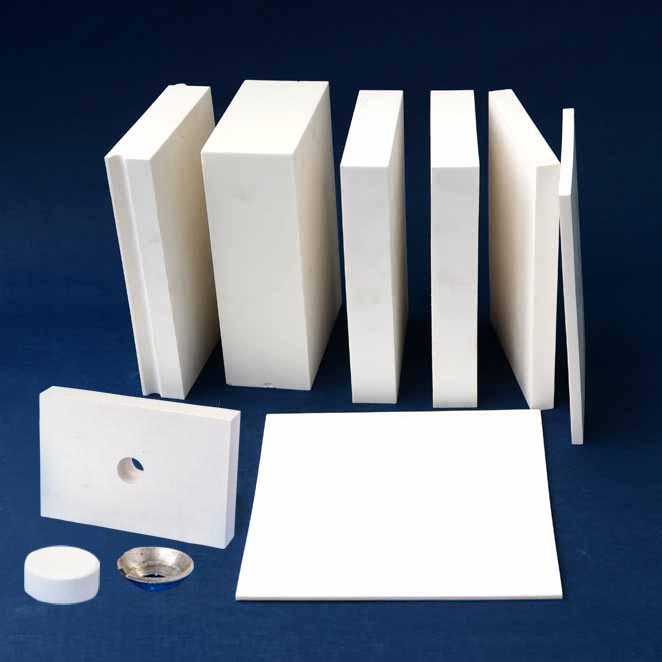

Besides the strength, craftsmanship, economy, we also need to consider the abrasion resistance when choose the machinery parts. In order to combine equipment surface strengthening with high performance and cost-effectiveness, Chemshun recommends the use of wear resistant ceramic materials.

The abrasion resistant ceramic materials choice

Industrial ceramics has good advantage of light weight, low density, high hardness . so it is considered as first choice for wear protection. Now market it exists many kinds of abrasive ceramics with different materials ,like alumina ceramics, silicon carbide ceramics, zirconia ceramics and so on . which kind of materials you should choose ? chemshun tell you that above industrial ceramics has different property, it is better to consider your machine working environment, like handling material size, area size , strength, height etc.Then you can get your working machine biggest work efficiency and bring largest profit .

Post time: Nov-12-2022