Ceramic materials, mainly refers to industrial ceramics or advanced ceramics, they are used in various industrial fields, where mechanical strength and resistance to external forces (such as corrosion) are the main functional requirements. The wear resistance is the main performance index to measure the ceramic material. Usually people use hardness to judge the wear resistance and strength of alumina ceramic materials. That is, the higher the hardness, the better the wear resistance. So how to test the hardness parameters of wear-resistant ceramics?

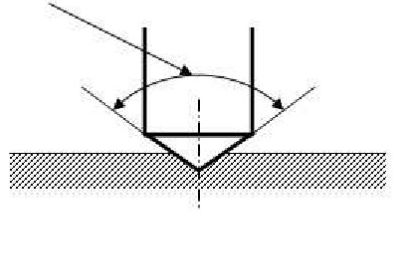

Hardness is one of the most important and frequently measured properties in alumina ceramics. It can be defined as a measure of the yield stress of any ceramic or material. Hardness characterizes the resistance of a ceramic to fracture, deformation, densification and displacement. Generally speaking, Vickers and Knoop methods are widely used for hardness testing of ceramics. The Vickers technique is the most common. It measures the hardness of ceramics or other materials by measuring the size of the indentation left by the indenter. It is suitable for small parts and thin sections. It uses a diamond indenter and a light load to create an indentation on the material being tested. The hardness value can also be a measure of the depth of the indentation caused by the indenter.

According to the different needs of the market for the performance of alumina ceramics, Chemshun Ceramics produces AL2O3 92%, AL2O3 95% alumina wear resistant ceramic materials. The alumina content affects the hardness of the ceramic material to a certain extent, that is, the wear resistance. Customers can choose wear-resistant ceramics with different alumina content according to the needs of the working environment.

Post time: Oct-13-2022