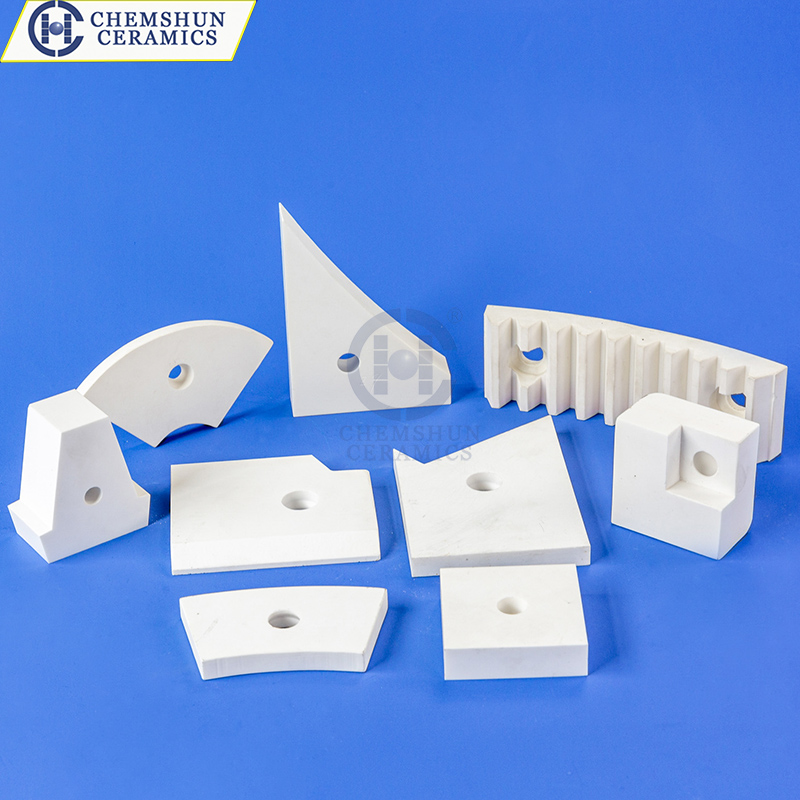

Alumina ceramics is a kind of engineering ceramics, and ordinary daily use of ceramic products are very different. Alumina ceramics are also known as wear-resistant ceramics, because it has excellent wear resistance, corrosion resistance, high temperature resistance, so it is widely used in steel, coal, mining, cement, chemical and other industries, is a good choice for industrial wear resistance.

The process of making alumina ceramics is generally divided into several steps: powder preparation, pressing, sintering.

To make wear-resistant ceramics with good performance, it is necessary to select good alumina powder, whose particle size is usually 1μm or less. In the process of powder preparation, different additives should be added to prepare powder with different properties.

Alumina ceramics can be formed in a variety of ways. The commonly used methods are dry pressing molding, grouting molding, extrusion, isostatic pressing molding, injection method, rolling method, hot pressing method, gel method, etc. Molding supply is the key to prepare high performance wear-resistant ceramics. Generally speaking, alumina ceramics made by dry pressing and isostatic pressing process have higher hardness and wear resistance.

Sintering alumina ceramics is also a very important step. Among them, the control of sintering temperature is the key point, determines the density, structure and service life of the ceramic.

Each step of the production of alumina ceramics requires professional control and detection, in order to obtain excellent wear-resistant ceramics.

Post time: Apr-17-2023