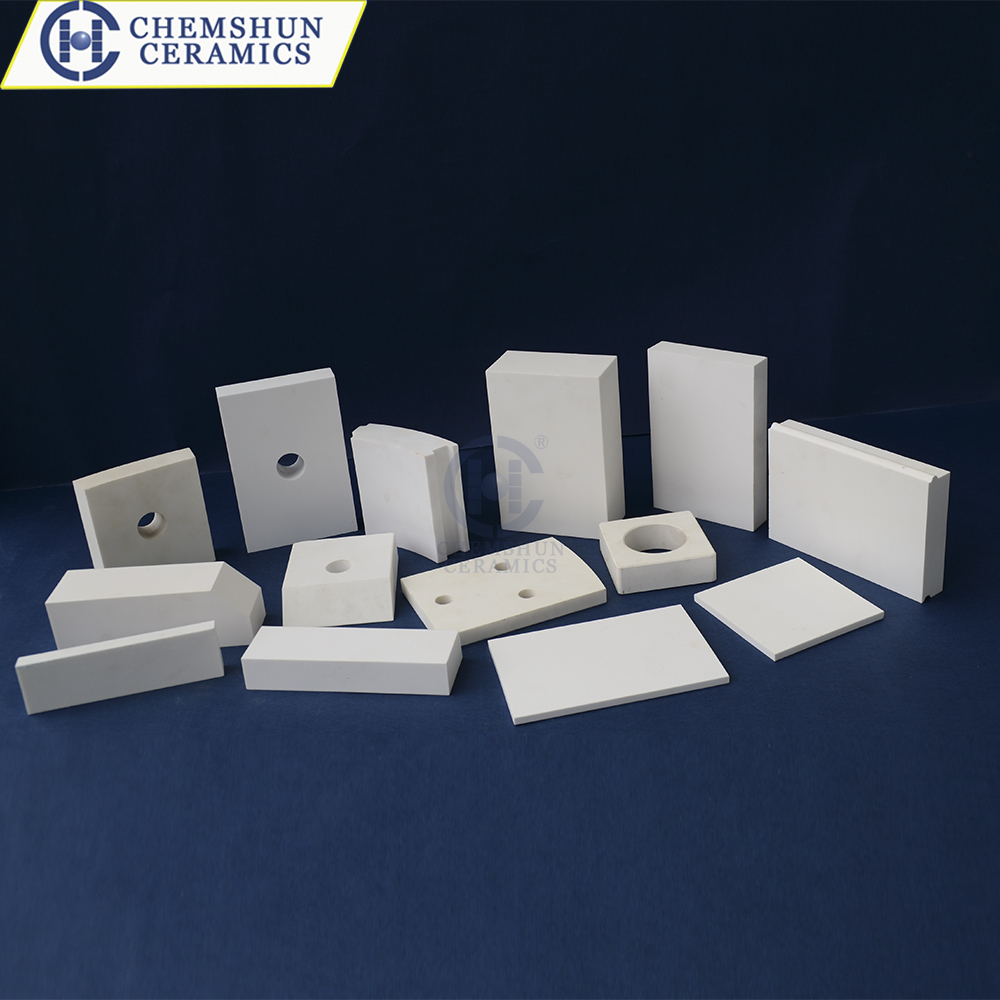

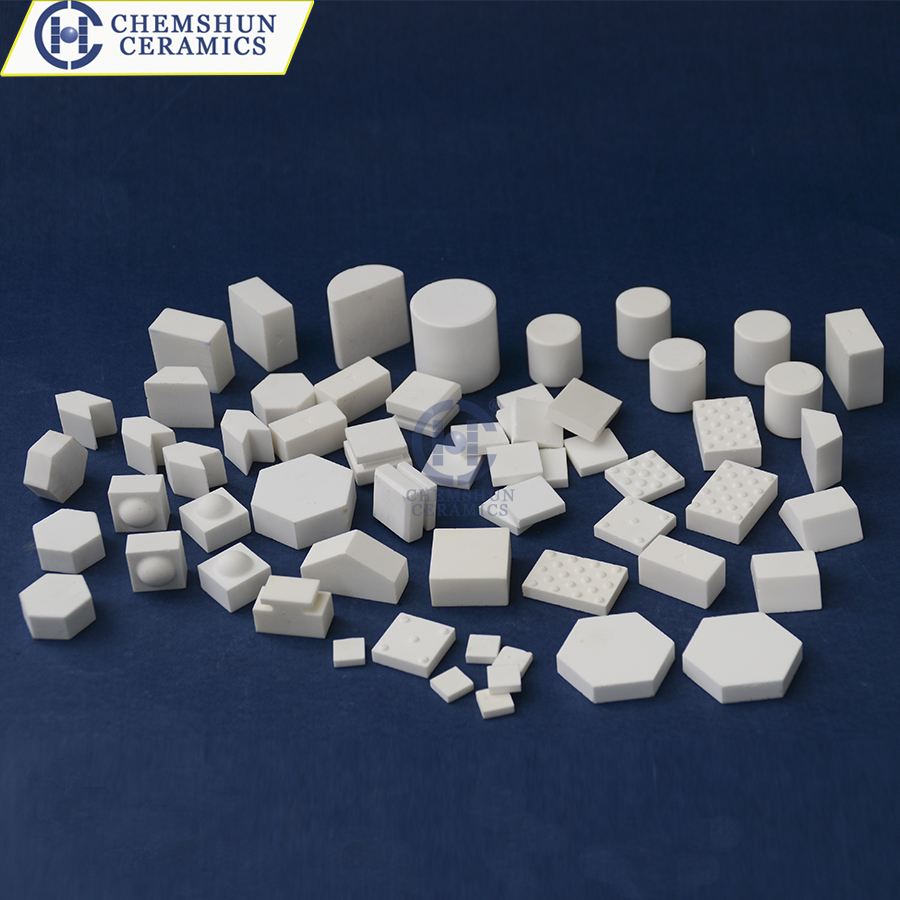

In modern industrial production, the efficient operation and service life of equipment are crucial. As a high-performance material, alumina ceramic liner plates play a vital role in various industrial sectors due to their outstanding properties, providing reliable solutions to enhance production efficiency and reduce costs.

Properties of Alumina Ceramic Liner Plates:

High Hardness and Wear Resistance

Alumina ceramic liner plates exhibit extremely high hardness, with a Mohs hardness rating of approximately 9, second only to diamond. This feature enables it to maintain a stable physical form in the face of strong erosion and wear of materials and effectively resist wear. For example, in industries such as coal and mining, where materials cause severe friction against equipment walls during transportation, ordinary liner plates are often quickly worn through. In contrast, alumina ceramic liner plates can withstand prolonged wear, significantly extending equipment maintenance cycles and service life.

Corrosion Resistance

Alumina ceramics demonstrate excellent chemical stability and exhibit strong resistance to most acids, alkalis, salts, and other chemical media. In industries such as chemical processing and metallurgy, where corrosive substances are frequently encountered during production, alumina ceramic liner plates can withstand erosion from these media. This ensures the integrity of internal equipment structures, maintains normal operation, and avoids safety hazards (e.g., leaks) and production interruptions caused by corrosion.

Excellent Thermal Resistance

Alumina ceramics have low thermal conductivity, providing effective insulation. In high-temperature industrial environments, such as kiln equipment in steel and cement industries, the use of alumina ceramic liner plates can minimize heat loss, improve energy efficiency, and reduce energy consumption. Additionally, their superior insulation properties protect equipment shells from deformation or damage caused by prolonged exposure to high temperatures.

Post time: Mar-24-2025