As a kind of high performance environmental protection material, wear-resistant ceramics play an increasingly important role in the environmental protection industry by virtue of their excellent physical and chemical properties. Its excellent wear resistance, corrosion resistance, high temperature stability and other characteristics make it an ideal choice for many environmental protection equipment and systems.

Wear-resistant ceramics are widely used in waste incineration power plants. The key parts in the waste incinerator, such as the furnace, flue, etc., are subjected to high temperature, high-speed airflow and fly ash erosion during the incineration process, and are easy to wear and corrosion. Wear-resistant ceramics have extremely high hardness and wear resistance, which can effectively resist these harsh conditions and extend the service life of the equipment. At the same time, the corrosion resistance of wear-resistant ceramics also makes it able to resist the corrosion of corrosive gases and fly ash generated during the waste incineration process, protecting the equipment from damage. This not only reduces the frequency of equipment maintenance and replacement, improves the operation efficiency of the power plant, but also meets environmental requirements and reduces the waste generated by equipment wear and tear.

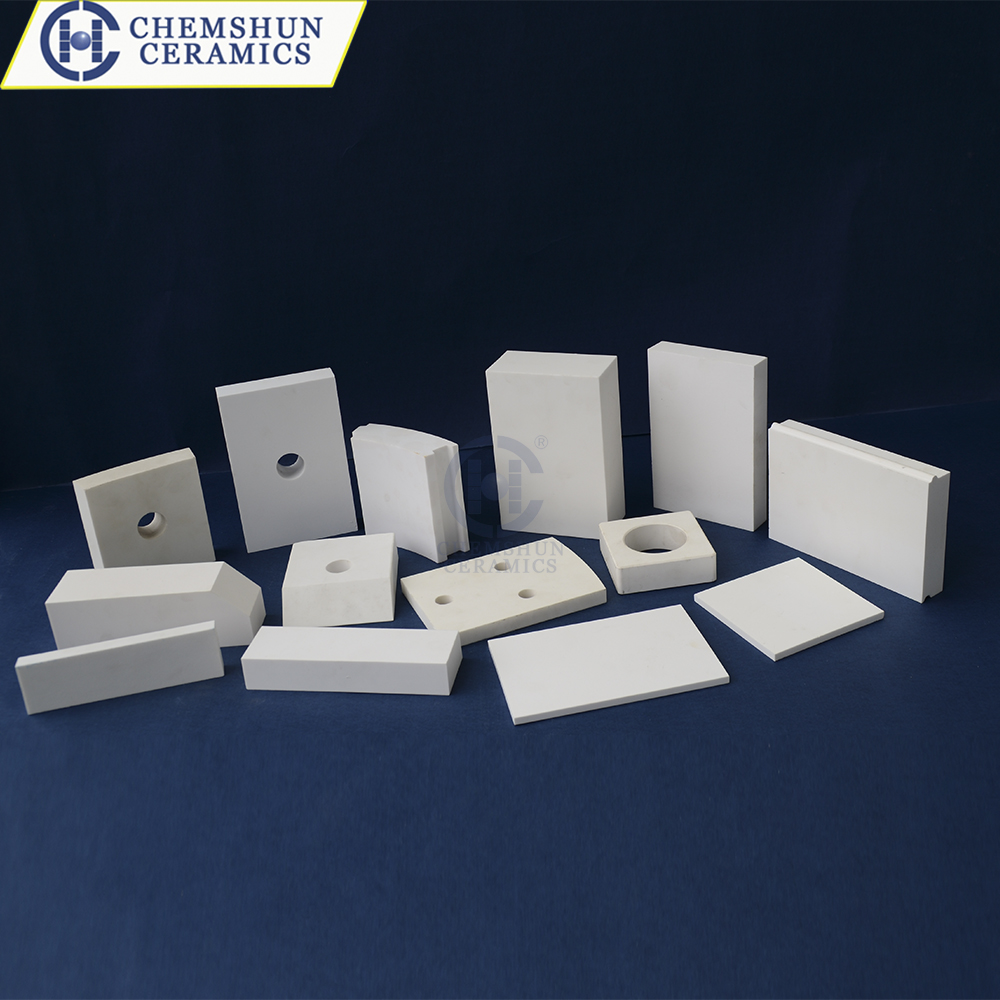

In addition, wear-resistant ceramics are also widely used in other areas of the environmental protection industry. For example, in the chemical industry, wear-resistant ceramics can be used as the lining of storage tanks, transportation pipelines and other equipment to improve the service life of products and reduce production costs. In the cement industry, wear-resistant ceramics can be used for the inner wall of the cement mill, the grinding rod and other parts to improve production efficiency and reduce energy consumption. In coal mining, metallurgy and other industries, wear-resistant ceramics are mainly used for parts with large wear, such as wear plates, wear shops, etc., effectively reduce the wear of equipment and extend the service life.

It is worth mentioning that alumina wear-resistant ceramics also play an important role in the environmental protection industry. Alumina wear-resistant ceramics have extremely high hardness and wear resistance, which can significantly extend the service life of industrial equipment. Its excellent corrosion resistance enables it to remain stable in acid and alkali environments and is not easy to be eroded by chemicals. This further reduces environmental pollution and promotes the realization of energy conservation and emission reduction targets. At the same time, the stable performance of alumina wear-resistant ceramics under extreme conditions such as high temperature and high pressure makes it widely used in high-energy industries such as electric power, chemical industry and metallurgy.

In general, the application of wear-resistant ceramics in the environmental protection industry not only improves the operating efficiency and reliability of equipment, reduces production costs and energy consumption, but also promotes the process of energy conservation and emission reduction and green development. With the continuous progress of technology and the increasing requirements of environmental protection, the application prospect of wear-resistant ceramics in the environmental protection industry will be broader. In the future, wear-resistant ceramics are expected to be applied in more fields and make greater contributions to the cause of environmental protection.

Post time: Jan-08-2025