With the rapid development of the semiconductor industry, the scale of the industry has increased rapidly, and semiconductor manufacturing equipment has continued to evolve into precision and complexity. Because ceramics have the advantages of high hardness, high elastic modulus, high wear resistance, high insulation, corrosion resistance, low expansion, etc., it can be used as parts of silicon polishing machine, epitaxial/oxidation/diffusion heat treatment equipment, lithography machine, deposition equipment, semiconductor etching equipment, ion implantation machine and other equipment, so the research and development and production of precision ceramic parts directly affect the development of semiconductor industry. The technical requirements of its preparation are getting higher and higher.

High purity alumina, 99.7%-99.9% alumina.

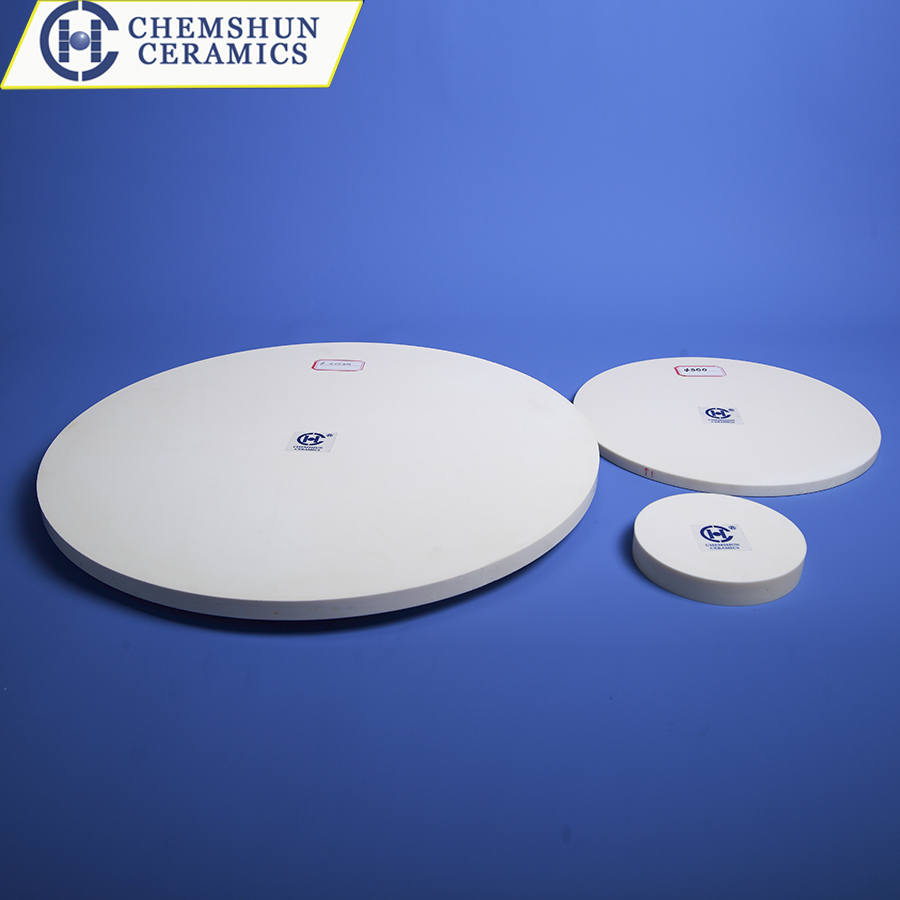

High mechanical strength, high wear resistance, high electrical insulation, high chemical stability, good heat resistance and corrosion resistance. At present, the use of ceramic grinding disc grinding semiconductor silicon wafer is the most superior and cutting-edge grinding method. The double-sided grinding process is used to grind the cut silicon wafer, and the quality of the grinding wafer is improved by improving the grinding process (disc material, grinding fluid, grinding pressure and grinding speed, etc.). In particular, the use of ceramic plates instead of cast iron plates, to avoid grinding on the main surface of the wafer caused by scars or pollution, reduce the introduction of metal ions, can reduce the subsequent processing of silicon, shorten the subsequent process (corrosion) time, improve production efficiency, and reduce the loss of silicon processing, greatly improve the utilization of silicon.

High alumina wafer polishing plate is used in semiconductor, petroleum, chemical, photovoltaic, liquid crystal and other industries, such as mechanical parts, electronic parts, microwave induction disk, insulation materials and other parts, semiconductor devices, vacuum equipment, liquid crystal manufacturing equipment and other parts. Large size and high purity alumina ceramics have important application value in sapphire industry and semiconductor chip industry. It is a key support and consumable for chemical mechanical polishing (CMP) of sapphire and semiconductor silicon wafers. Large size and high purity alumina ceramics can also be used as an alumina substrate for LCD.

Post time: Jun-27-2024