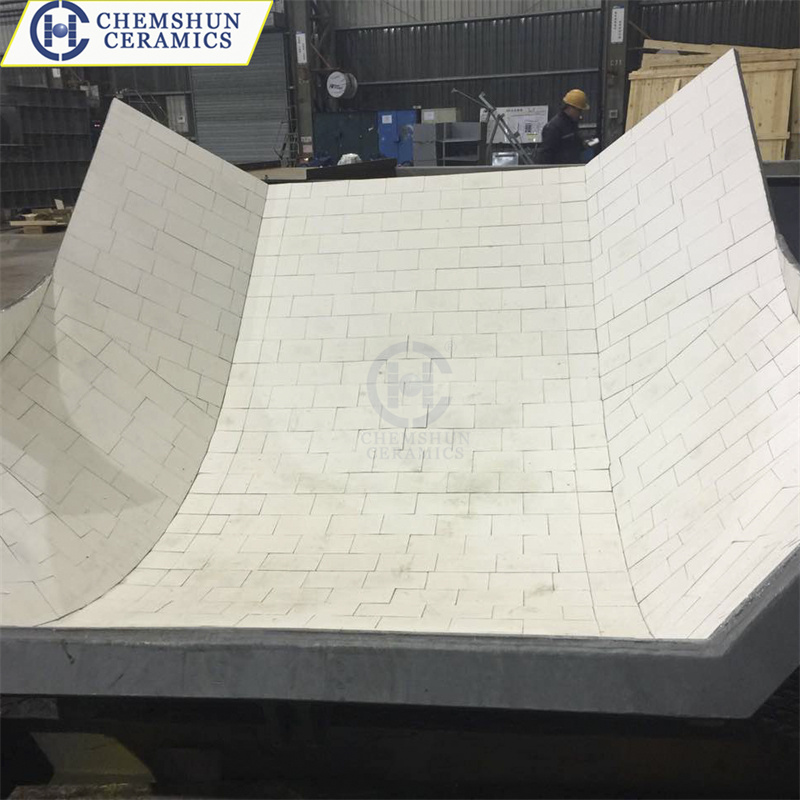

OEM Customized Square Lagging Ceramics - 99.7% Alumina Ceramic Baseboard – Chemshun

OEM Customized Square Lagging Ceramics - 99.7% Alumina Ceramic Baseboard – Chemshun Detail:

Application

As the Alumina Substrate for LCD panel (PFD,PDF,TFT…) manufacturing equipment.

For Large LCD industry glass substrate transfer manipulator.

For lithography equipment.

Feature

High purity and chemical durability

High Mechanical Strength and Hardness

High Corrosion Resistance

High Voltage Resistance

High Temperature Up to 1700ºC

Extremly Abrasion Resistance Performance

Excellent Insulation Performance

Large size

Large size

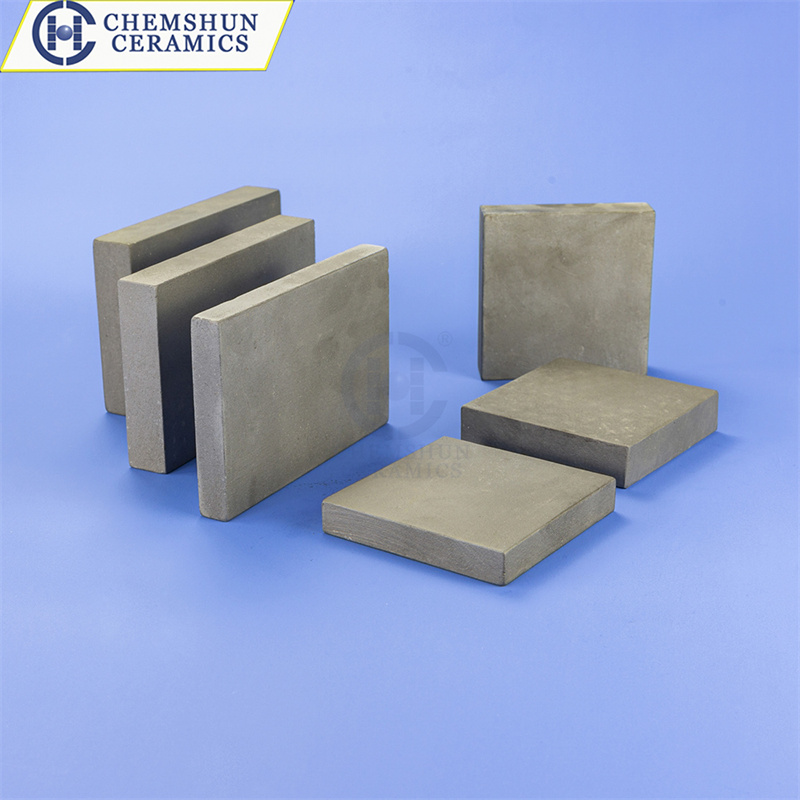

| Product name | Chemshun large size high purity Alumina ceramic substrate ceramic panel |

| Material | 99.7% alumina |

| Normal Size | 1200x500x20, 1400x900x30, customized size accepted. |

| Color | Ivory |

| Application | LCD panel (PFD,PDF,TFT…) manufacturing equipment. |

| Min.Order | 1Pic |

Chemical / physical Information

| Unit | 99.7 Alumina Ceramics | ||

| General Properties | Al2O3 content | wt% | 99.7-99.9 |

| Density | gm/cc | 3.94-3.97 | |

| Color | - | Ivory | |

| Water absorption | % | 0 | |

| Mechanical Properties | Flexural Strength(MOR) 20 ºC | Mpa(psix10^3) | 440-550 |

| Elastic Modulus 20ºC | GPa (psix10^6) | 375 | |

| Vickers Hardness | Gpa(kg/mm2) R45N | >=17 | |

| Bending Strength | Gpa | 390 | |

| Tensile Strength 25ºC | MPa(psix10^3) | 248 | |

| Fracture Toughness (K I c) | Mpa* m^1/2 | 4-5 | |

| Thermal Properities | Thermal conductivity(20ºC) | W/mk | 30 |

| Coefficient of Thermal expansion(25-1000ºC) | 1x 10^-6/ºC | 7.6 | |

| Thermal Shock Resistance | ºC | 200 | |

| Maximum use temperature | ºC | 1700 | |

| Electrical Properities | Dielectric Strength (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

| Dielectric Constant(1 MHz) | 25ºC | 9.7 | |

| Volume Resistivity | ohm-cm (25ºC) | >10^14 | |

| ohm-cm (500ºC) | 2×10^12 | ||

| ohm-cm (1000ºC) | 2×10^7 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for OEM Customized Square Lagging Ceramics - 99.7% Alumina Ceramic Baseboard – Chemshun , The product will supply to all over the world, such as: New Delhi, Iran, Peru, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Write your message here and send it to us