OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Pipe Equipment – Chemshun

OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Pipe Equipment – Chemshun Detail:

Product Description

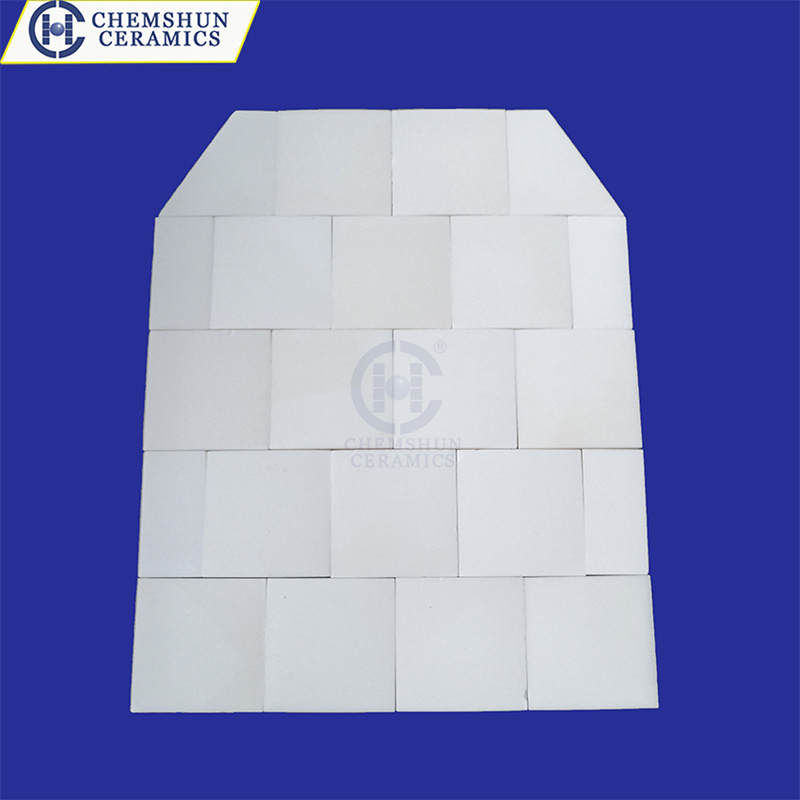

| Product Name | Alumina Ceramic Tile for Lining Pipe |

| Size | 150×53/49.38x13mm, 150×53/49x25mm,150×50/46x25mm,100×35/32x13mm |

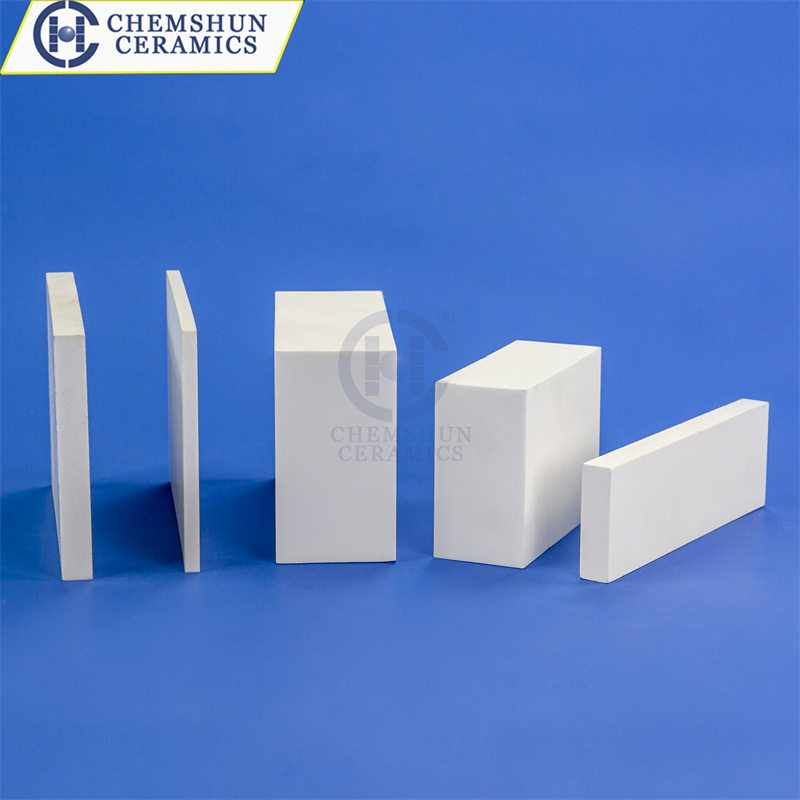

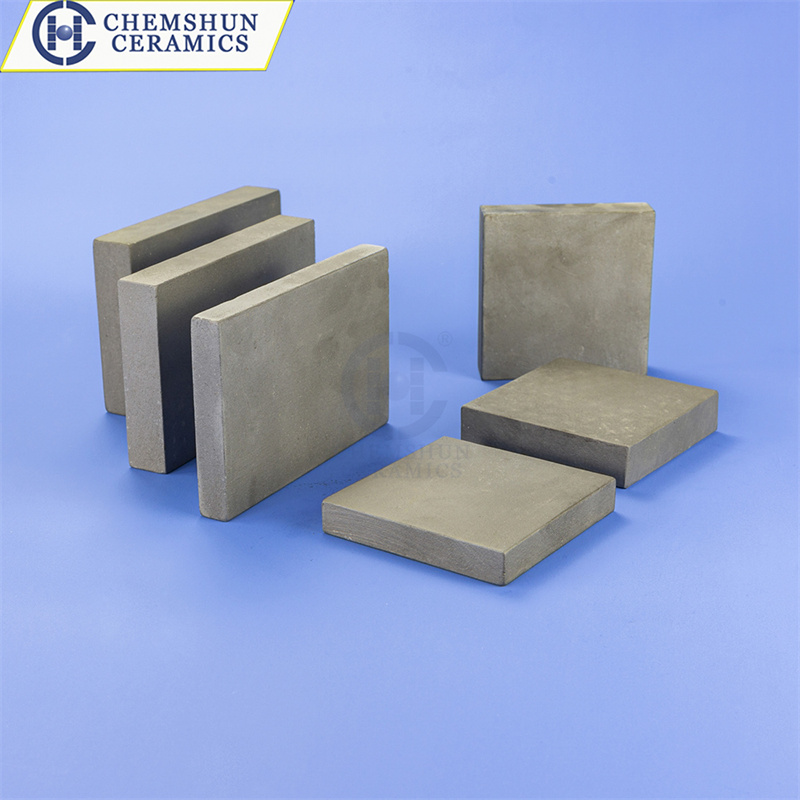

| Description | Chemshun Alumina Ceramic Tile for Lining Pipe is also called Alumina Ceramic Pipe Tile. It is used with advantage of the trapezoidal-shape and the benefit feature of the alumina Ceramic in lining steel pipe to avoid corrosion and abrasion. And then reduce the maintenance cost and prolong the use life of the pipes. |

| Feature | 1.High purity; 2.High hardness; 3.Simple shape |

| Benefit | 1.Excellent anti-resistant and corrosion resistance; 2.Excellent anti-impact; 3.Easy to pack and installation for using due to the simple shape and this could reduce the time cost; 4.Its abrasion is 266 times than that of manganese, 171.5 times to high chrome cast iron. |

| Application | 1.Used to be line in steel pipe |

| Related Industry | Steel plant, power plant, refinery factory, cement plant, mining industry, port industry,etc. |

| Facilities for lining | Chute, hopper, bunker, stacker, Belt conveyor, Coal feeder, Distributor, Pipe and elbow, Burner, Valve |

Specification

| Technical | Unit | 92AL | 95AL |

| Alumina | % | 92 | 95 |

| Density | g/cc | 3.60 | 3.68 |

| Flexural Strenght | Mpa | 275 | 300 |

| Rock well hardness | R45N | 75 | 78 |

| Vickers Hardness (HV10) | Kg/mm2 | 1050 | 1120 |

| Fracture Toughness | Mpa.m1/2 | 3-4 | 4-5 |

| Thermal Expansion Coefficient(25-1000ºC) | 1X10-6/ºC | 8.0 | 8.1 |

| Max. Use Temp. | ºC | 1250 | 1250 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Pipe Equipment – Chemshun , The product will supply to all over the world, such as: Greece, Bangladesh, New Orleans, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we've been striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Write your message here and send it to us