PriceList for Alumina Hexagon Mats - Alumina Ceramic Lining Pieces – Chemshun

PriceList for Alumina Hexagon Mats - Alumina Ceramic Lining Pieces – Chemshun Detail:

Advantages

1) Excellent abrasion resistance;

2) Excellent impact resistance;

3) Excellent hardness;

4) Excellent corrosion resistance (resist the strong alkaline, strong acid slag and liquefied materials);

5) Excellent heat resistance (up to 1500℃);

6) Smooth surface can reduce barrage and friction coefficient to prolong the device working life;

7) Low density can reduce the lined equipment weight and improve the equipment working effectiveness.

Technical datas

|

Properties |

Unit |

Chemshun 92 |

Chemshun 95 |

|

Al2O3 |

% |

92 |

95 |

|

Density |

g/cm3 |

3.6 |

3.65 |

|

Moh’s Hardness |

Grade |

9 |

9 |

|

Products |

Size in mm (L*W*T) or (S*T) |

||

|

Ceramic Square Tile |

10*10*2~10, 17.5*17.5*2~15, 20*20*2~10, 33*33*5~25, etc. |

||

|

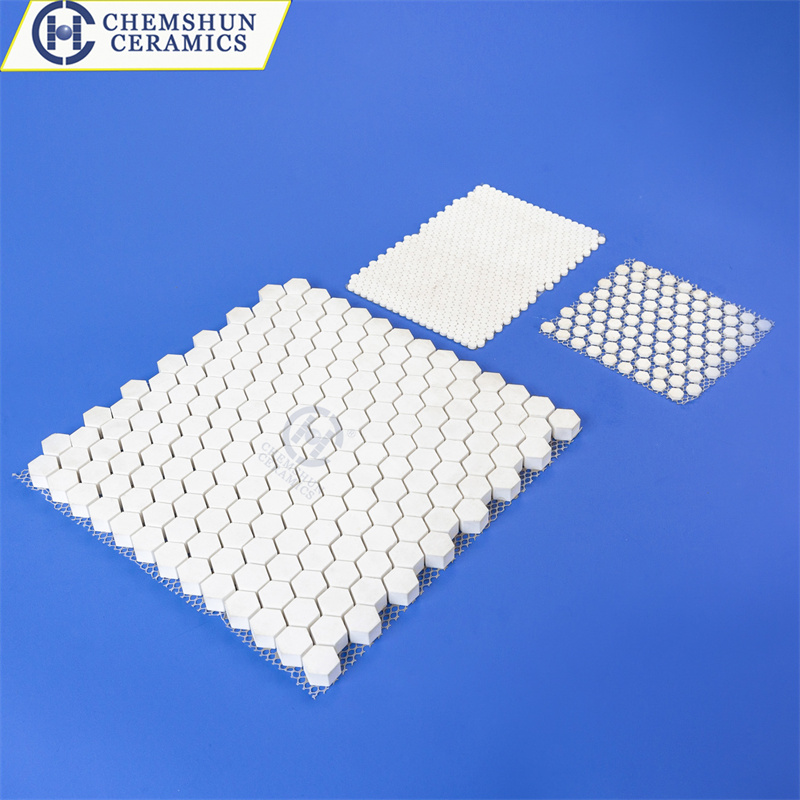

Ceramic Hexagonal tile |

6*3~6, 11*3~25, 12*3~25, 19*3~25, etc. |

||

|

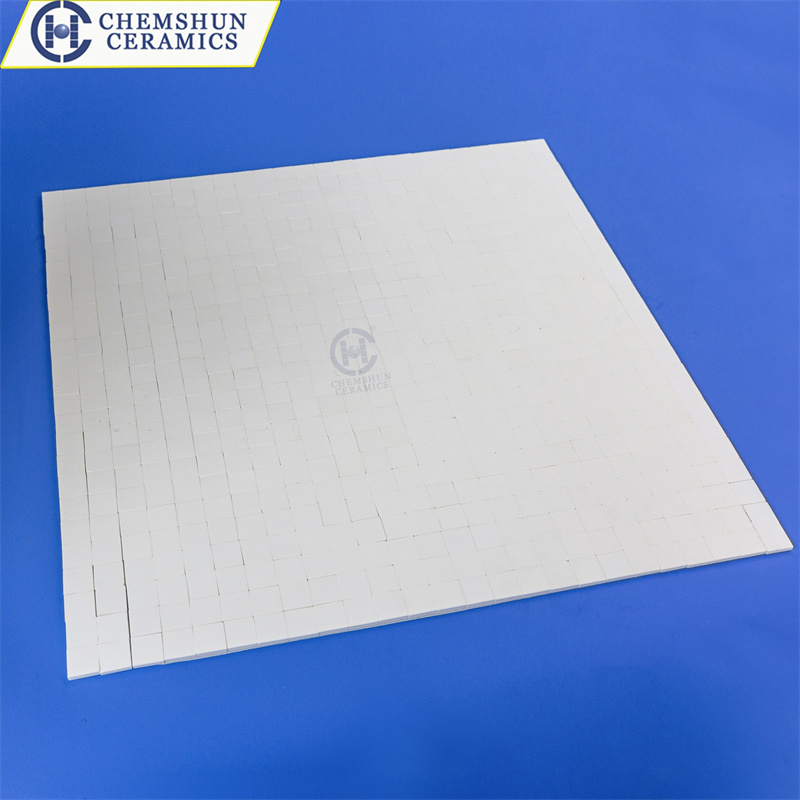

Hex/Square Tile Mat |

32*32*32, 40*40*40, etc. |

||

|

Material of Mats |

Paper, Nylon Mesh, Acetate Cloth, etc. |

||

Application

|

Application Industry from Chemshun |

||

|

Industry |

Equipment System |

Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute,Bunker,Pulley lagging,discharge cone |

| Raw mill system | Feed chute,Retaining ring,Scraper plate,Seal ring,Pipeline,Bucket guard,Cyclone,Powder concentrator body,Bunker | |

| Cement mill system | Chute,Bunker,Fan vane wheel,Fan casing,Cyclone,Circular duct,Conveyer | |

| Ball mill system | Pulverizer exhauster’s body and vane wheel,Powder concentrator’s body,Pulverized coal’s pipeline,Hot air duct | |

| Sintering system | Inlet/Outlet bend,Wind value plate,Cyclone,Chute,Dust collector’s pipe | |

| Afterheat system | Separator’s pipeline and wall | |

| Steel | Raw material feeding system | Hopper,Silo |

| Batching system | Mixing bunker,Mixing barrel,Mixing disk,Disk pelletizer | |

| Sintered material transport system | Hopper,Silo | |

| Dedusting and Ash discharge system | Dedusting pipeline,Bend,Y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone,Separation buffles,Outlet pipe,Pulverized coal’s pipeline,Burner cone | |

| Ball mill | Classifier,Cyclone separator,Bend,Powder concentrator’s Inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine,Coal Hopper,Coal Feeder,Orifice |

| Ball mill system | Separator’s pipe,elbow and cone,Coal mill’s elbow and straight tube | |

| Medium-speed mill | Coal mill body,Separation buffles,Cone,Pipeline,Elbow | |

| Fall mill | Pulverized coal’s Pipeline and Elbow | |

| Dedusting system | Dedusting’s Pipeline and Elbow | |

| Ash discharge system | Fan duster’s shell,Pipeline | |

| Port | Transporting material system | Bucket wheel machine’s disk and hopper,Transfer point’s hopper,Unloader’s hopper, |

| Smelting | Transporting material system | Measuring hopper,Coke hopper,Vibrating screen’s chute,Head valve,Intermediate Bin,Tail bin |

| Batching system | Batch hopper,Mixing machine | |

| Burning system | Ash bucket,Pump calcine tube,Hopper | |

| Dedusting system | Dedusting’s Pipeline and Elbow | |

| Chemical | Transporting material system | Hopper,Silo |

| Dedusting system | Dedusting’s Pipeline and Elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine,Coal Hopper,Coal Feeder,Silo |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper,Silo |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

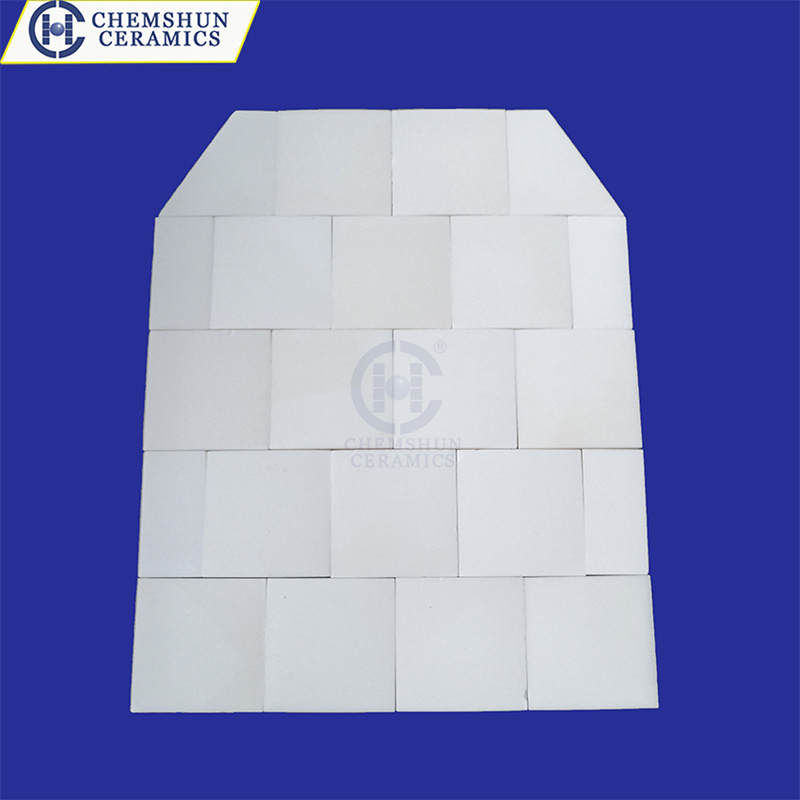

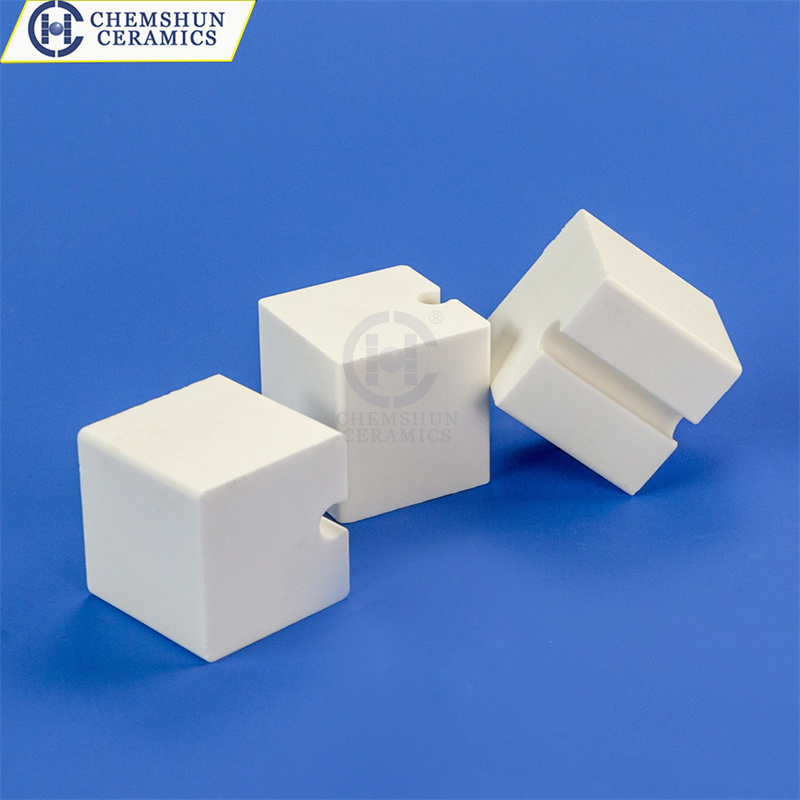

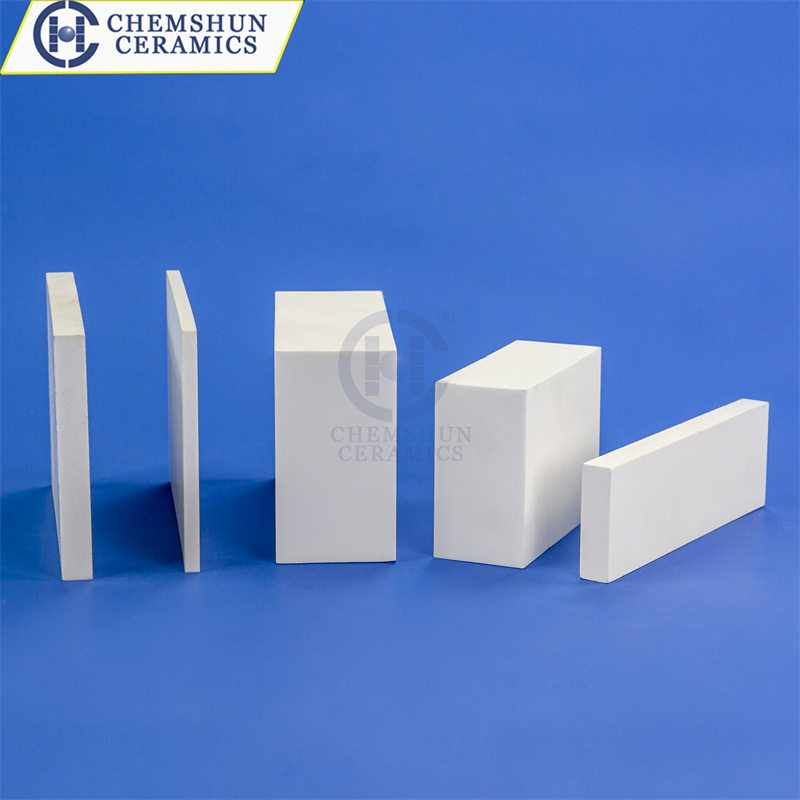

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for PriceList for Alumina Hexagon Mats - Alumina Ceramic Lining Pieces – Chemshun , The product will supply to all over the world, such as: Peru, San Francisco, Mombasa, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.