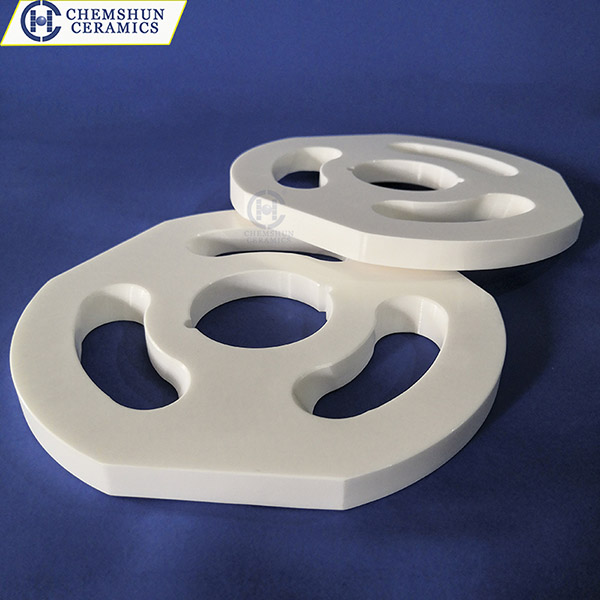

Zirconia Ceramic Ring

Product Description:

The company takes the world’s advanced ceramic technology and process as the innovation goal, adopts professional equipment and testing instruments, strictly controls the product quality, and provides Y-ZR, A-ZR, FZTA and silicon carbide and other high strength, wear resistance, corrosion resistance, high temperature resistance engineering ceramic parts to the domestic and foreign markets.Among them, A-ZR ceramic material is widely used in various industrial fields with its excellent cost performance and reliable quality.

With our production capability through precision grinding machines, we are able to provide many different level precision zirconia ceramic parts to meet customers’ high precision assembly needs.

Main Features:

1) High strength;

2) Corrosion resistant;

3) High wear resistance, good self lubricity.

Application fields:

Suitable for valve core, mold, cutting tool, bearing, shaft, sealing ring, liner, etc.

Comparison of comprehensive performance parameters of different zirconia ceramic materials:

| A-ZR | Y-ZR | FZTA | |

| ZrO2 Content | 90% | 94.5% | 40% |

| Density g/cm³ | >5.9 | >6.0 | >4.8 |

| Hardness (HRA) | >89 | >89 | >89 |

| Bending Strength (MPa) | >1100 | >1000 | >600 |

| Modulus of Elasticity (GPa) | 230 | 200 | 180 |

| Coefficient of Thermal Conductivity (W/Wm.k) | 4 | 3 | 6 |

| Fracture Toughness (MPa.m½) | 10 | 8 | 3.5 |

| The Corrosion Resistance | A+ | A | A+ |

| High Temperature Wear Resistance | A+ | A | A |

| Resistance to Wear at Normal Temperature | A+ | A+ | A |

| Fatigue Resistance | A+ | A | A+ |